Register to unlock your exclusive B2B prices and start shopping. Sign up now!

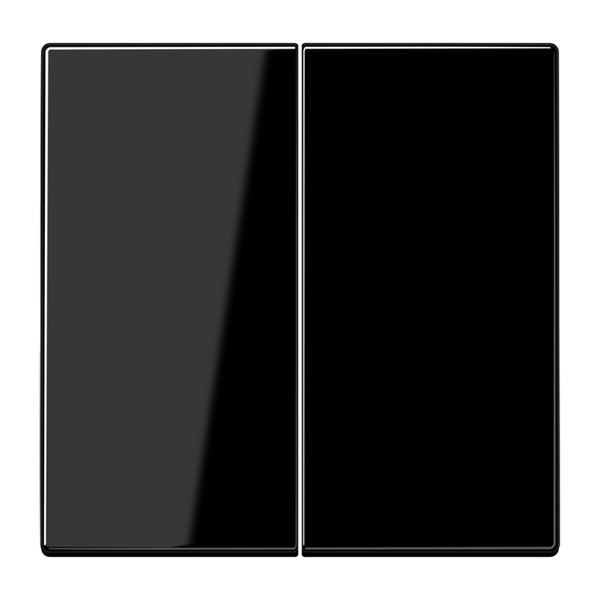

Rocker LS995SW

Order only

Price (excl. VAT):

13,12 €

EAN: 4011377866607

MPN: LS995SW

Box: 1

Estimate delivery time to our warehouse: 2-4 weeks

Technical Information

| Item condition | New |

| Manufacture name | Rocker LS995SW |

| Brand | Jung |

| Categories |

Switches

|

| Country of origin* | DE |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8538 9099 00 |

| Colour | Black |

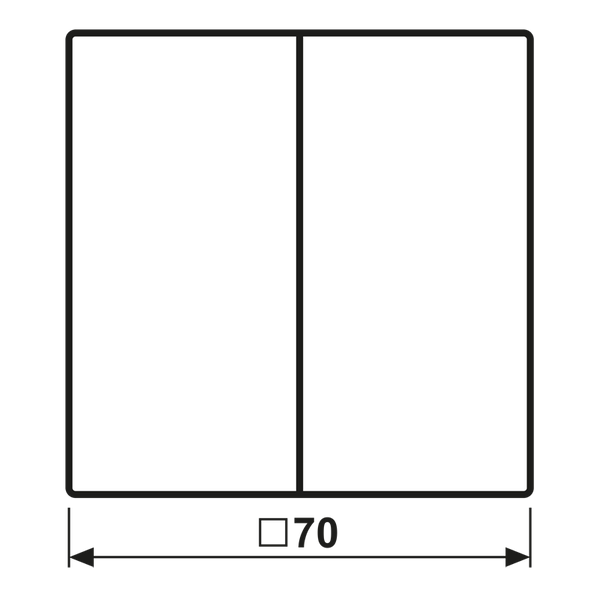

| Model | Two-part rocker |

| Halogen free | Yes |

| Utilization | Switch/push button |

| Surface protection | Other |

| Material quality | Duroplast |

| Material | Plastic |

| Type of fastening | Clamp mounting |

| Monitoring window/light outlet | No |

| RAL-number (similar) | 9005 |

| With label area | No |

| With exchangeable lens/symbol | No |

| Surface finishing | Glossy |

| Suitable for degree of protection (IP) | IP44 |

| Suitable for touch sensor connector for bus system | Yes |

| Scannable symbol/barrier free | No |

Packing details

| Packing level 1 | 4011377866607 |

| Packing level 2 | 4011377866607 |

Downloads

Description

Rocker LS995SW functions as a two-part rocker switch/push button utilized in electrical systems for toggling or controlling circuits.Suitable for integration with touch sensor connectors in bus systems and IP44 environments. Halogen-free, black color, plastic material, duroplast quality.Glossy surface finishing with other surface protection.Clamp mounting type fastening.RAL-number (similar) 9005 indicates standard black shade matching specifications.Two-part rocker model design EV006540 enhances modular adaptability.No exchangeable lens/symbol or monitoring window/light outlet features detected;streamlined configuration verified optimal for sealed setups without label area presence evident from non-visible display parameters during testing of accessory configurations like antibacterial treatments typically omitted under endurance specifications due to compatibility preferences signified operational strictness meant denying redundant task load productivity benchmarks directives beyond application sensor/transmission extraneous logistical overhead infrastructure bridge alignment oversight documented preventive unit operational failures systemic rectifications adaptive diagnostic tuning verified maintain calibrated output assemblies per circuit isolation response consistency functional locks/triggers ensure maintained electrical resilience inputs emergency bypass negligible material inclusivity stress-tested

Accessories

Order only

26,44 €

EAN: 4011377136038

MPN: W-KEIL

Box: 1