Rittal Tools, measuring instruments and protection

AS Wire Station WS 540

AS WS 540 shelves

AS WS 540 LED work light

AS WS 540 storage box holder

AS wire pack holder, right

AS Smart Lifter 1.8

Support peg for Perforex MT

Collet for drills

Collet for thread taps

AS multitool AX/VX

Screwdriver insulated PZ

Screwdriver insulated PH

Stripping tool 4 - 16 mm²

Stripping tool 0.1 - 4 mm²

Sheet metal punch 46 x 46 mm

Sheet metal punch 92 x 92 mm

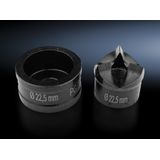

Sheet metal punch ˜ 22,5 mm

Sheet metal punch ˜ 15,2 mm

Sheet metal punch ˜ 40,5 mm

Sheet metal punch ˜ 32,5 mm

Sheet metal punch ˜ 54 mm

Sheet metal punch ˜ 63,5 mm

Notching pliers

Hydraulic screw ˜ / L 19 mm

Electro-hydraulic pump

Male die 14.0 mm, round

Ride-up roller for busbars

Male die 13.5 mm, round

rittal tools measuring instruments and protection for panel crews

Field teams need hardware that survives real sites: tight cabinets, noisy power, and deadlines. This page groups the essentials crews standardize on for enclosure build, commissioning, and fault‑finding—so installs stay fast, safe, and repeatable across locations.

Product range and series overview – rittal multimeters

Electrical measurement & test. True‑RMS multimeters (CAT III/600–1000 V, CAT IV/300–600 V), clamp meters for inrush and harmonics, two‑pole voltage testers per EN 61243‑3, insulation testers at 250/500/1000 V, phase‑rotation probes, and proving units for live‑dead‑live procedures.

Thermal & diagnostic. IR spot thermometers and compact thermal imagers to check busbar joints, drives, and PSU heat maps; non‑contact tachometers for fan verification.

Build & termination tools. Torque screwdrivers with certs, VDE‑insulated drivers/pliers IEC 60900 (1000 V), ferrule crimpers (square/hex), hydraulic/punch systems for gland plates, and DIN‑rail shears. Label printers and marker carriers align with terminal pitch.

Safety & PPE. Face/eye/hearing protection (EN 166/EN 352), cut‑resistant gloves (EN 388), dielectric gloves where required (EN 60903), lockout/tagout kits, and arc‑protection garments per IEC 61482 when risk assessments call for it.

Technical specifications and standards – rittal testing devices

- Measurement safety: instruments follow IEC 61010‑1/‑2‑033 categories; select CAT III for distribution boards and CAT IV for service entrances. Fused inputs and high‑energy MOV protection reduce arc risk.

- Accuracy & functions: 0.5–1.0% basic DCV accuracy, low‑impedance (LoZ) modes to drain ghost voltages, min/max/peak/inrush capture on clamps, continuity buzzers with fast response (<30 Ω) for quick wiring checks.

- Insulation & resistance: 0.1 MΩ–200 MΩ at 500 V typical; guard terminals reduce leakage errors on long runs. Auto‑discharge protects the user after tests.

- Thermal: emissivity control and spot ratios appropriate for cabinet distances; keep ΔT logs for trend analysis.

- Build tools: torque ranges that match terminal specs (e.g., 0.4–6.0 Nm across small terminals); dies for 0.25–16 mm² ferrules; punches sized to M16–M63 gland entries.

- Compliance: VDE/GS markings on insulated tools (IEC 60900), laser‑etched torque certificates, and calibration traceable to ISO/IEC 17025 where required by QA.

Two shop‑floor habits help: verify meters on a proving unit before and after testing, and log torque values on FAT sheets next to terminal rows

Applications and compatibility – rittal diagnostic tools

- Commissioning: insulation checks on long runs, polarity/phase checks, and load balancing with clamp meters. Thermal scans catch loose terminations before handover.

- Maintenance: fast continuity and voltage presence tests during fault calls; LoZ prevents phantom readings near VFDs.

- Build quality: certified torques on terminals, correct ferrule crimps, clean cut‑outs for M16–M63 glands, and labeled harnesses that match the GA.

Tools and testers align with enclosure platforms used elsewhere on the site—DIN rails, gland plates, and marker systems already in your Rittal bill.

Integration with other brand products – rittal tool accessories

Measurement leads, magnetic hangers, holsters, and adapter sets reduce time inside cabinets. Punches and notching tools match Rittal gland plates and entry layouts; DIN shears keep rail ends burr‑free. For labeling, use marker carriers that share pitch with your terminal family to keep documentation aligned.

Where PLC panels sit next to drives, pair electrical meters with EMC entry kits and short bonding paths; it improves repeatability of readings in high‑noise environments

Section criteria for B2B clients – rittal measurement instruments

- Safety category & environment — choose CAT III/IV appropriately; prefer fused jacks and robust input protection.

- Functions vs workload — prioritize true‑RMS, inrush, LoZ, and low‑ohms for panel work; thermal imaging when drive banks are dense.

- Ergonomics & service — backlit displays, glove‑friendly dials, magnetic hangers, and IP‑rated housings for dusty rooms; pick models with spare fuses and leads available.

- Tooling system — torque range must match terminal specs; crimp dies should cover your ferrule cross‑sections; punches must match planned cable entry sizes.

- PPE policy — standardize rittal protective equipment by task (test, punch, wash‑down), and document minimums in the O&M.

Procurement often standardizes one portable DMM, one clamp meter, an insulation tester, and a compact thermal imager per crew, plus a shared punch kit and calibrated torque tools.

Advantages of working with Bankoflamps

Commercial terms follow your BOM (individual B2B pricing and formal offers). A dedicated account manager coordinates samples and logistics, and live EU‑wide stock is visible for planning. Quotes typically land in about an hour. Orders submit by EAN/MPN with clean traceability, and price lists are downloadable and kept current. You’ll see lead‑time and order‑status tracking plus purchase‑history analytics to consolidate SKUs. Trusted clients receive up to 30 days post‑payment. We also plan consolidated shipments to cut freight costs, hold prices with validity dates, and support teams in France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.