RELPOL Industrial Automation

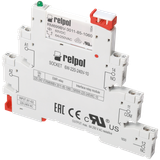

Interface relay: consists with:universal socket 6WB-220-240V-U and relay RM699BV-3011-85-1005

Socket for relay: R2N. Solder terminals. 29,6 x 21,5 x 18,1 mm. Two poles. Rated load 12 A, 250 V AC

Socket for relays: R2M. For PCB. Dimensions 29,6 x 14 x 10,5 mm. Two poles. Rated load 5 A, 250 V AC

Socket for relay: R4N. For PCB. Dimensions 29,6 x 21,5 x 11 mm. Four poles. Rated load 6 A, 250 V AC

relpol automatics and control for panel builders and OEMs

Relpol’s control gear is built for dependable switching and signaling in distribution boards, machine panels, and building systems. The portfolio covers DIN‑rail relays, sockets, timing and monitoring modules, solid‑state options, and compact interface relays that cleanly separate PLC I/O from field loads. Procurement teams use Relpol where life‑cycle cost, socketed maintenance, and wide coil options beat closed, proprietary blocks.

Product range and series overview – relpol control systems

Three functional families typically make up project bills:

- Interface and power relays – plug‑in and relay‑module formats with change‑over contacts for 6/10/16 A loads. Versions include electromechanical (EMR) for general purpose and SSR for silent, high‑cycle switching. Coil sets span 12/24 V DC and 24/110/230 V AC. Socket systems with clip retainers and markers speed replacement without rewiring.

- Timing, monitoring, and logic modules – multi‑range timers (on‑delay, off‑delay, interval, star‑delta), voltage and phase monitors, and watchdog relays for pump/fan protection. Rotary or DIP configuration supports commissioning without laptops; scale markings simplify handover.

- Switching and interposing devices – slim 6–12 mm interface relays for PLC outputs, power relays for contactor pre‑stages, and isolating relays for safety interlocks (per project design). LED status and test buttons aid diagnostics during FAT/SAT.

For relpol industrial automation tasks, engineers mix interface relays at the PLC row, timers for sequence control, and SSRs where acoustic noise or high switching rates would wear mechanical contacts.

Technical specifications and standards – relpol automation components

- Contacts & ratings: SPDT/DPDT up to 10–16 A at 250 V AC (resistive), with inductive derating curves. AgNi or AgSnO contact systems for endurance; gold‑flash options for low‑level signals. Electrical endurance typically ≥100k cycles at nominal load; mechanical into the millions.

- Coils: DC coils with built‑in suppression (flyback or RC) depending on model; AC coils optimized for low heat rise. Wide coil ranges ease late design changes.

- Insulation: dielectric strength commonly 2.5–4 kV between coil and contacts; creepage/clearance and tracking resistance suitable for OVC II/III, PD2 environments (see datasheet per model).

- Formats: plug‑in relays with keyed bases, or 6–12 mm slim DIN modules for dense PLC cabinets. Terminals accept 0.5–2.5 mm² conductors; test points provided on many sockets.

- Compliance: design intent aligned with IEC 61810 (EMR), IEC 60947‑5‑1 (control circuit devices), IEC 61373/60068 for vibration/shock where specified, and EN 61010 context for measurement/control. EMC for electronic timers aligns with EN 61000 family; marking supports EU CE and UL where applicable.

- Environment: typical ta −25…+55/70 °C depending on density; housings IP20. Conformal coatings or sealed covers available on selected references.

Panel notes from site work: reserve 10–20% coil‑power margin on 24 VDC rails to avoid brown‑out during cold starts; label sockets and keep identical types grouped to reduce maintenance errors.

Applications and compatibility – relpol relays and controllers

- Building services: AHU/FCU staging, boiler interlocks, blinds/shade control, lighting groups. Interface relays protect BMS and PLC outputs from inrush and back‑EMF.

- Machinery & OEM: conveyor gates, heater switching, solenoid valves, and motor auxiliaries. SSRs handle rapid thermal cycling without chatter.

- Infrastructure: pump alternation, level alarms, and fault signaling for water/wastewater plants; voltage/phase monitors reduce nuisance trips.

Relpol sockets interoperate with common 35 mm DIN rails and panel footprints. Where contactors are oversized for small loads, an interposing relay reduces cost and improves diagnostic clarity.

Integration with other brand products – relpol switching devices

Relpol modules sit between field devices and higher‑power gear. Use interface relays ahead of contactors and VFD digital inputs to protect logic cards. Timing modules align start/stop sequences with soft‑starter ramps, and voltage monitors guard against supply anomalies before PLC power supplies. For signaling, combine relay outputs with tower lights and buzzers to give maintainers fast visual states.

On lighting control panels, pair interface relays with DALI/0–10 V gateways as isolation stages; relay contacts switch mains while controls stay SELV.

Selection criteria for B2B clients – relpol control modules

- Load type and current – define resistive/inductive and choose contact material and rating accordingly. Check inrush for LED drivers and transformers.

- Coil system – DC vs AC, coil consumption, and suppression type. Verify coil burden against auxiliary PSU capacity.

- Form factor – plug‑in + socket for serviceable panels, or slim modules for density. Keep terminal style consistent across rows.

- Diagnostics – prefer variants with LED, mechanical flag, and test button for maintenance.

- Standards & approvals – match IEC category to the market (EU/UL). Document derating vs ambient and enclosure grouping.

Stock planners often standardize a 24 VDC coil family plus a 230 VAC variant for retrofit jobs, keeping spares lean while covering most scenarios.

Advantages of working with Bankoflamps

- Individual B2B pricing and custom offers tailored to project scope.

- Personal account manager for samples, submittals, и logistics.

- Real‑time stock visibility across EU warehouses.

- Quick quote response (~1 hour) for tender agility.

- Fast order placement by EAN/MPN with clean traceability.

- Downloadable, always up‑to‑date price lists for ERP syncing.

- Lead‑time tracking and order status updates for site scheduling.

- Purchase‑history access and analytics to consolidate SKUs.

- Post‑payment (up to 30 days) for trusted clients.

- Consolidated shipment management to reduce freight costs.

- Stable pricing with validity dates; we serve France, the Baltics, Germany, Spain, Italy, Belgium, and the Netherlands.