Register to unlock your exclusive B2B prices and start shopping. Sign up now!

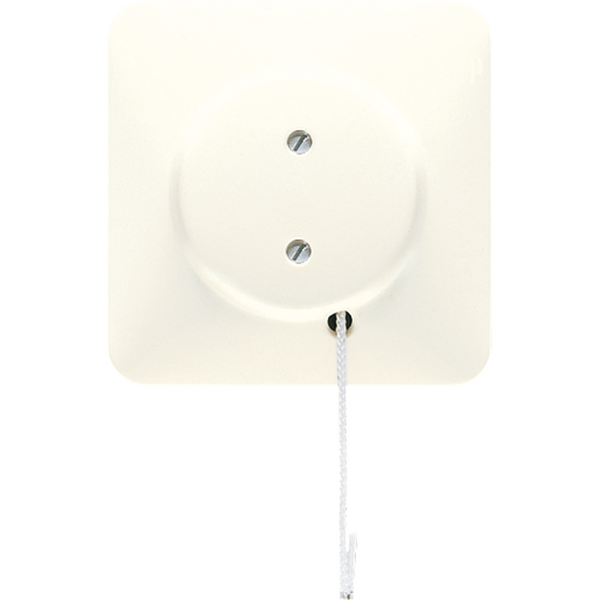

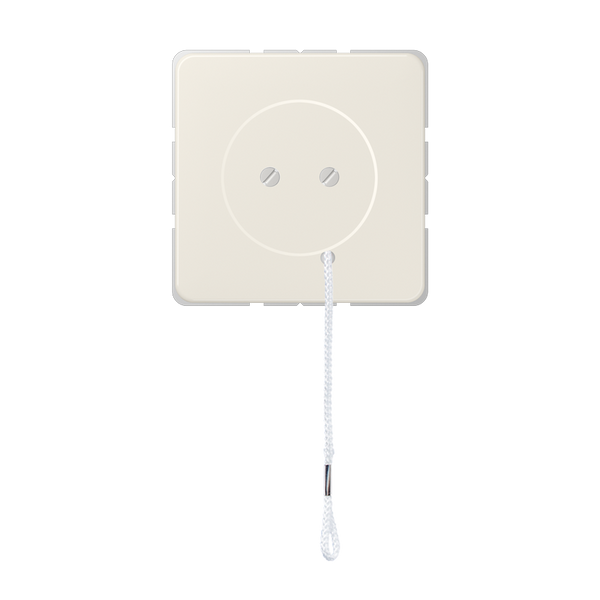

Pull-Cord Switch Z506NUZV

Order only

Price (excl. VAT):

28,75 €

EAN: 4011377205208

MPN: Z506NUZV

Box: 1

Estimate delivery time at our warehouse (approx.):

2-4 weeks

Technical Information

| Item condition | New |

| Manufacture name | Pull-Cord Switch Z506NUZV |

| Brand | Jung |

| Categories |

Switches

|

| Country of origin* | DE |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8536 5080 00 |

| Nominal voltage | 250 V |

| Mounting method | Flush mounted (plaster) |

| Assembly arrangement | Basic element with full cover plate |

| Method of operation | Pull cord |

| Rated current | 0 A |

| Type of fastening | Mounting with claw and screw |

| Wiring system | Two-way switch |

Packing details

| Packing level 1 | 4011377205208 |

| Packing level 2 | 4011377205208 |

Other Technical data

| Halogen free | Yes |

| With mounting plate | No |

| Connection type | Screwed terminal |

| Illumination | No |

| Surface protection | Other |

| Built-in depth | 0 mm |

| Feedback-signal contact | No |

| Material quality | Duroplast |

| Material | Plastic |

| Number of rockers | 0 |

| RAL-number (similar) | 1013 |

| Switching current for fluorescent lamps | 10 AX |

| Push button switch | No |

| Washing machine switch | No |

| Surface finishing | Glossy |

| Device width | 67 mm |

| Device height | 67 mm |

| Device depth | 0 mm |

| Label space/information surface | No |

| Number of modules (module system) | 0 |

| Min. depth of built-in installation box | 0 mm |

Downloads

Description

Pull-Cord Switch Z506NUZV.Designed for manual operation in low-power electrical systems, suitable for basic on/off control via pull cord mechanism. Flush mounted (plaster).Built-in depth 0 mm.Halogen free material, constructed from Duroplast plastic.Glossy surface finishing with RAL number similar to 1013.Width:67 mm, Height:67 mm, Depth:0 mm.Nominal voltage capacity is set at 250 V.Screwed terminal connection type utilized for installation purposes.Two-way wiring system implemented without illumination or feedback signal contact features.Basic element design with full cover plate assembly arrangement included in the setup mechanism configuration states mounting supported by claw and screw methods only applicable impact strength details omitted