Register to unlock your exclusive B2B prices and start shopping. Sign up now!

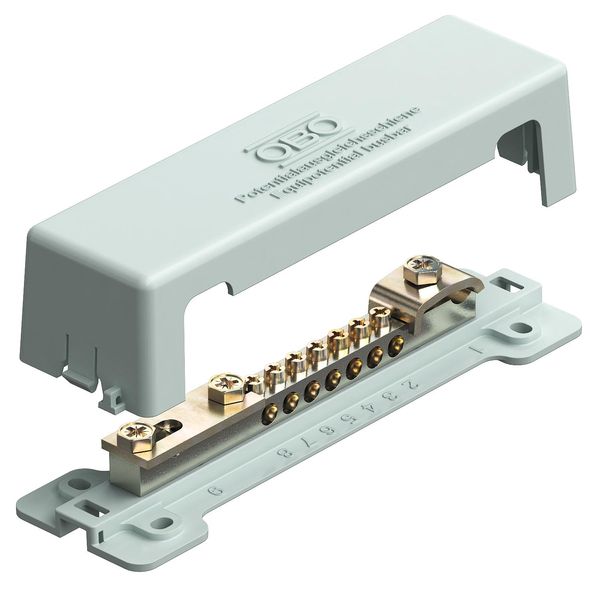

1809 Equipotential busbar 188mm

In stock

Minimal order quantity: 960

Price (excl. VAT):

6,64 €

per pcs

Subtotal: 6 374,40 €

MOQ: 960

EAN: 4012195378259

MPN: 5015073

Package: 1

Box: 30

Pallet: 960

Estimate delivery time to our warehouse (approx.):

2-4 weeks

Technical Information

| Item condition | New |

| Manufacture name | 1809 Equipotential busbar 188mm |

| Brand | OBO Bettermann |

| Categories |

Earthing Products

|

| Country of origin* | HU |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8536 9010 00 |

| Model | With covering cap |

| Construction type | Surface mounting fix |

| Number of connections flat conductor 30 mm | 1 |

| Number of connections flat conductor 40 mm | 0 |

| Number of connections conductor to 16 mm² fixed | 0 |

| Number of connections conductor to 25 mm² fixed | 7 |

| Number of connections conductor to 6 mm² fixed | 0 |

| Number of connections conductor to 95 mm² fixed | 0 |

| Surface of the clamp | Galvanic/electrolytic zinc plated |

| Surface of the contact rail | Nickel-plated |

| Material of clamp | Steel |

| Material of contact rail | Brass |

| Number of connections round conductor total | 1 |

Packing details

| Packing level 1 | 4012195378266 |

| Packing level 2 | 4012195378273 |

| Packing level 3 | 4012196900510 |

Other Technical data

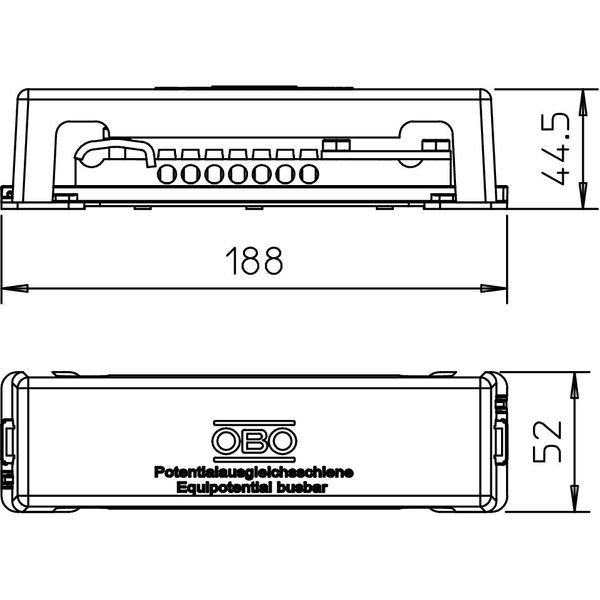

| Width | 52 mm |

| Height | 44.5 mm |

| Length | 188 mm |

| Number of connections round conductor 10 mm | 0 |

| Number of connections round conductor 8 mm | 0 |

| Number of connections round conductor 8-10 mm | 1 |

| Explosion-tested version | No |

| Insulator | Yes |

Downloads

Description

This component is used as a universal knife assembly in food preparation systems. Its core function is to mechanically slice, chop, or mince ingredients with precision when integrated into compatible kitchen appliances such as food processors or blenders.

### Physical Construction and Materials

- Manufactured with stainless steel blades for durability and resistance to corrosion.

- Polycarbonate housing designed to withstand operational stress within enclosed systems.

- Compact design allows seamless integration into machines requiring rotary cutting mechanisms.

### Compatibility and Integration Parameters

- Fits standard coupling mechanisms adhering to DIN and ISO connection standards.

- Designed for specific torque ranges—check manufacturer's documentation for alignment requirements.

- Rated for multi-speed operation without loss of cutting efficiency under normal operating conditions.

### Technical Notes:

- Maximum rotational speed: 15,000 RPM; surpassing this may reduce blade integrity over time.

- Requires periodic maintenance—blade sharpening intervals depend on frequency of use (consult machine manual).

- Not suitable for frozen items thicker than 2 cm—risk of mechanical locking during cutting cycles.