OSRAM Transformer for halogen metal halide

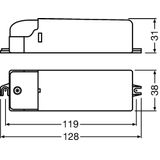

ET-PARROT® 105/220…240 I

ET-PARROT® 70/220…240 I

OSRAM Transformers and Ballast Units for Halogen & Metal-Halide

OSRAM power gear covers two different worlds that often get mixed up in specs: low-voltage halogen transformers and HID (metal-halide) control gear. One converts mains to 12 V for halogen; the other limits current and provides ignition for discharge lamps. Selecting the right OSRAM unit prevents nuisance trips, lamp flicker, and premature failures in luminaires and p

OSRAM Halogen Transformers — electronic vs magnetic

Use-case: 12 V halogen (MR16, AR111, capsule) in shop fits, display cases, accent lighting, cabinet lighting.

Types you’ll see in BOMs:

- Electronic transformers (ET): compact, light, high-frequency output (~30–50 kHz). Typical load windows 20–60 W, 35–105 W, 50–150 W.

- Magnetic/torodial (conventional) transformers: 50/60 Hz iron core, heavier, tolerant of long cable runs and odd loads.

Parameters that matter (halogen):

- Input: 220–240 V AC, 50/60 Hz (site voltage tolerance ±10 %).

- Output: 11.5–12 V AC (RMS).

- Load window: respect min and max; electronic units will not start below the minimum wattage.

- Dimming: check compatibility:

- Leading-edge (TRIAC/phase-cut) — many ETs support it.

- Trailing-edge (ELV) — cleaner with less buzz; confirm on datasheet.

- 1–10 V / DALI — only on specific drivers; halogen rarely uses these.

- Wiring length: electronic units have short permissible 12 V leads (typically ≤2 m) to avoid capacitive effects; magnetic allows longer runs

- Thermals: ta (ambient) and tc (case) limits; keep airflow—don’t bury the unit under insulation.

- Protection: short-circuit/overload/over-temp auto-reset on ETs; fusing on magnetic.

When to choose which:

- Electronic — tight spaces, weight sensitive, many small 12 V heads on short leads, phase-cut dimming expected

- Magnetic — long cable runs, mixed load types, harsh EMI, or legacy dimmers that misbehave with electronic gear.

Typical halogen mistakes:

- Running one 35 W lamp on a 35–105 W ET → below-min-load flicker/no-start.

- Trailing-edge dimmer on an ET not rated for it → strobing, transformer stress

OSRAM Metal-Halide Control Gear — ballasts, ignitors, electronic gear

Use-case: HQI/HCI/MH lamps in halls, façades, high-bays, floodlights.

Topologies:

- Electromagnetic ballast (choke) + ignitor + capacitor: classic HID set.

- Ignitor variants: superimposed (parallel), series, semi-parallel — match to lamp/luminaire wiring.

- PF correction: add capacitor in control box; target PF ≥0.9 for large banks.

- Electronic control gear (ECG) for HID: drives lamp at controlled frequency, warm-start/End-of-Life protection, often higher efficacy and better colour stability.

Parameters that matter (metal-halide):

- Lamp wattage & voltage class: eg. 70/150/250/400 W; lamp arc voltage defines ballast current.

- Ignition pulse: kV window must meet lamp spec (cold and hot re-strike).

- Lead length/capacitance limits between ignitor and lamp (especially superimposed types).

- Thermals: ta/tc on gear tray; enclosed canopies can exceed ta quickly.

- Mains: 50/60 Hz taps and ±10 % tolerance; voltage sag during warm-up is a common nuisance.

- EMC/safety: gear should meet IEC 61347 family; luminaire per IEC 60598; lamps IEC 62035.

When to choose which:

- EM ballast + ignitor — simple, robust, cost-effective, easy field service, widely compatible.

- Electronic HID gear — tighter current control, faster stabilisation, lower flicker, better lamp life in premium installations.

Typical HID mistakes:

- Mismatching lamp and choke wattages → over-current and blackened tubes.

- Using series ignitor in a luminaire wired for superimposed → no-start.

- Exceeding max ignitor-to-lamp cable length → random misfires

- Skipping PF capacitors on big cabinets → penalties and nuisance breaker trips.

OSRAM Lighting Transformers vs OSRAM Ballast Units — quick decision table

Task | Use OSRAM Halogen Transformer | Use OSRAM HID Ballast/ECG |

| Powering 12 V MR16/AR111 | ✔ | – |

| Dimming with phase-cut wall dimmers | ✔ (check dimmer type) | – |

| Driving metal-halide (HQI/HCI/MH) | – | ✔ (+ ignitor) |

| Long secondary cable runs | Magnetic transformer | EM ballast (check ignitor leads) |

| Tight thermal space, light weight | Electronic transformer | Electronic HID gear (if lamp allows) |

OSRAM Mounting, Wiring, and Protection Notes

- Class I vs Class II gear: confirm earth continuity; some ETs are double-insulated (Class II) — wiring differs.

- Ingress / location: IP20 in dry ceiling voids; IP54/65 only if specified. Keep out of insulation voids unless gear is “IC” rated.

- Fixation: firm mounting to metal tray or luminaire backplate for heat sinking; maintain clearance around tc point.

- Separation of circuits: route 12 V halogen leads away from mains where possible; for HID keep ignitor leads short and shielded if specified.

- Service labeling: mark lamp wattage, ballast code, ignitor type, capacitor value inside the luminaire or on the gear tray.

OSRAM Practical Comparisons

OSRAM Electronic Halogen Transformer vs Magnetic

- Size/weight: electronic is compact/light; magnetic is bulky/heavy.

- Compatibility: magnetic tolerates odd loads/long runs; electronic needs min load and short leads.

- Acoustics/EMI: electronic can buzz less but is EMI-sensitive; magnetic hums but shrugs off EM

- Efficiency: electronic typically higher at partial loads

OSRAM EM HID Gear vs OSRAM Electronic HID Gear

- Start/colour stability: ECG better; EM is adequate where cost rules.

- Maintenance: EM is field-serviceable with discrete parts; ECG is a single module swap.

- Controls: ECG can offer better dim or control options (model-dependent).

OSRAM Buyer Checklist (prevents callbacks)

- Define the lamp first

- 12 V halogen → transformer (check min/max load, dimming, cable length).

- MHHQI/HCI → ballast + ignitor (or ECG), PF capacitor as per sheet.

- 12 V halogen → transformer (check min/max load, dimming, cable length).

- Match ratings: mains, wattage, thermal class (ta/tc), IP.

- Confirm dimming method: leading/trailing-edge for halogen; HID dimming only on compatible ECGs

- Cable routing: respect lead-length limits; use suitable gauge and ferrules.

- Documentation pack: datasheet, wiring diagram, conformity (IEC 61347/60598/62035/EMC).

- Stock plan: unify families across sites to simplify spares and maintenance.

Common engineer errors: mixing “transformer” terminology into HID specs; ignoring min-load on ETs; using office dimmers on electronic transformers; overlooking ignitor topology on retrofits.

OSRAM Compatibility and Integration

OSRAM gear plays well with standard luminaires and panels: terminal sizes match common block types; mounting hole patterns suit gear trays; phase-cut dimmer lists are usually provided for ETs; HID gear pairing tables define ballast/ignitor/capacitor sets. In mixed-brand systems, verify lamp current and ignition windows, plus any EMC notes for long conduit runs

Why source OSRAM transformers and ballasts from Bank of Lamps

- EU warehouse (Latvia): popular ET load windows and HID wattages held for fast dispatch.

- Audit-ready files: conformity + wiring diagrams packaged for tender folders.

- Cross-reference help: we map your lamp lists (MR16/MH) to exact OSRAM gear (ET load window, ballast/ignitor pair, capacitor µF).

- Consolidated B2B supply: lamps + gear + brackets + glands in one PO to reduce freight/admin.