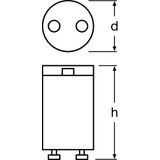

OSRAM Starters for lighting

OSRAM Starters for Lighting — fluorescent glow starters and HID igniters

OSRAM starters are the small but decisive parts that let discharge lamps strike reliably and live out their rated life. In practice you’ll deal with two families: fluorescent glow starters for magnetic (EM) T12/T8/T5 circuits, and HID igniters for high-intensity discharge lamps (HPS/MH) paired with conventional ballasts. The right part depends on lamp wattage, circuit topology (single vs series), mains voltage, and ambient/thermal limits. In real maintenance work, starters are rarely “selected” — they’re stocked. The job is to keep older fluorescent fittings starting cleanly, with minimal callbacks, and without wasting time diagnosing every single luminaire. For general-purpose replacement in mixed buildings where you just need a dependable spare to get fixtures running again, technicians often keep straightforward options like patron starters for lighting as an easy first swap when ignition becomes unreliable. When a site is managed as a repeatable maintenance routine — same corridors, same fittings, same switching schedule — the priority shifts to continuity and predictable behaviour across batches. In those cases, service teams frequently rely on widely supported ranges such as ledvance starters for lighting, chosen to keep replacement behaviour consistent over time. Some facilities treat starter choice as part of the electrical “discipline” of the building: standardised parts, clear documentation and a preference for components that align with professional electrical supply chains. For that approach, installers often look at options like kopp starters for lighting, used when the goal is clean, standardised servicing rather than ad-hoc fixes. In smaller upgrades and cost-controlled replacements — rental properties, small retail, storage rooms — the starter is simply a consumable that must be available and work without fuss. That’s why practical solutions such as kanlux starters for lighting are commonly used for everyday swaps in basic installations. And when maintenance teams deal with varied fixture ages and uncertain compatibility, they often keep an additional fallback option to cover edge cases and reduce repeat visits. In that role, technicians regularly use versatile spares like isolde starters for lighting, treating them as a practical reserve for mixed on-site realities.

OSRAM Fluorescent Glow Starters — where and when they’re needed

Glow starters are used only with electromagnetic (choke) ballasts. Electronic ballasts (HF) do not use them.

What they do (short version): preheat both lamp filaments, then open the circuit to create an inductive kick from the choke, striking the arc in the tube.

Typical OSRAM choices (conceptual mapping):

- OSRAM ST111-class: single-lamp circuits, ~4–65 W (e.g., 18/36/58 W T8).

- OSRAM ST151-class: series operation of two small fluorescent lamps, ~4–22 W each (sign boxes, compact fittings).

- Shatter-proof / ECO variants: same electrical window with improved safety and lifetime.

Selection rules that avoid callbacks:

- Match circuit type: single vs series. Putting a single-circuit starter into a series circuit (or the reverse) causes flicker and short life.

- Match wattage window: stay inside the printed W-range; over- or underspec leads to hard starting, blackened ends, and early EOL.

- Mains voltage: verify 220–240 V vs 110–127 V types when exporting or servicing imported fittings.

- Ta/Tc: enclosed bulkheads and damp locations run hotter; use starters with the right thermal class and IP context (typically IP20 inside the luminaire).

Installer notes:

- Replace starters together with the tube on maintenance rounds in older sites; tired starters are a common source of nuisance blinking.

- If tubes chatter at cold start, check the choke value and starter class before blaming the lamp.

OSRAM HID Igniters — for HPS/MH with conventional ballasts

HID lamps (high-pressure sodium, metal halide) need a high-voltage pulse to start. OSRAM igniters are paired with HID ballasts and come in three circuit topologies:

- Superimposed (SI): igniter in parallel; injects pulses onto the lamp leads while ballast stays “passive”. Best choice for long cable runs and retrofit flexibility.

- Series (S): igniter in the lamp circuit; lamp current flows through it. Simple wiring, but check exact ballast/igniter match.

- Semi-parallel (SPI): hybrid method used in some luminaires; follow OSRAM pairings.

Key parameters to check on any OSRAM igniter:

- Pulse (U_ign / U_peak): the open-circuit peak (e.g., several kV) must meet the lamp’s ignition requirement.

- Pulse train: repetition rate and duration — matters for cold weather or aged lamps.

- Max lead length / capacitance between igniter and lamp: exceeding this often equals “no start”.

- Temperature: ta/tc ratings; gear trays above ovens or in sealed canopies need the high-temp variants.

- Protection features: EOL and run-away prevention to avoid continuous pulsing into a failed lamp.

Common pairings in the field:

- HPS 70/100/150 W → matched ballast + superimposed igniter (preferred for outdoor poles).

- MH 150/250/400 W → series or superimposed depending on luminaire design; check OEM sheet.

OSRAM Electrical and Compliance Basics — what auditors check

- Glow starters: IEC/EN 60155 (glow-starters for fluorescent lamps)

- HID controlgear/igniters: IEC/EN 61347 series (safety of lamp controlgear) and relevant EMC clauses.

- Ingress & flammability (in luminaire context): IP as per IEC 60529, and glow-wire/UL94 for plastics used in holders/caps.

Why it matters: passing FAT/SAT in industrial sites often comes down to showing the starter/igniter data sheets line up with ballast and lamp ratings under these standards.

OSRAM Selection Logic — quick decision tree for buyers

- What lamp and ballast?

Fluorescent with EM choke → OSRAM ST-class glow starter.

- Fluorescent with HF electronic ballast → no starter used.

- HID (HPS/MH) with conventional ballast → OSRAM igniter (type per wiring).

- Power and circuit topology?

- Fluorescent: single vs series; wattage inside the printed range

- HID: check wattage, lamp family, ballast type, and cable run.

- Environment and maintenance

- Elevated ambient? Choose suitable ta/tc class.

- Long runs or poles? Prefer superimposed igniter with approved maximum lead length.

- Service model? Keep families unified across a site to simplify spares.

OSRAM Practical Comparison — starters vs igniters (and the pitfalls)

Aspect | OSRAM Fluorescent Starter (ST-class) | OSRAM HID Igniter |

| Application | T12/T8/T5 with EM choke | HPS/MH with conventional ballast |

| Function | Preheat & strike via choke kick | High-voltage pulses to lamp |

| Wiring sensitivity | Single vs series critical | Lead length/capacitance critical |

| Typical failures | Blink/no-start, blackened ends | No strike, rapid restrike pulsing |

| Typical mistake | Using series type in single circuit | Exceeding max cable length or wrong topology |

Avoid these two classics:

- Replacing “no-start” T8 tubes without changing an exhausted starter — fault returns in days.

- Putting a series igniter in a luminaire wired for superimposed — lamp never sees a proper pulse.

OSRAM Installation Pointers — saves time on site

- Label the gear tray: lamp W, ballast code, starter/igniter type. Future teams will thank you

- Tighten all push-in/screw terms after swaps; transient no-start can be plain loose copper.

- Cold conditions: choose igniters with robust pulse trains; HID lamps start slower below 0 °C

Why choose Bank of Lamps for OSRAM starters and igniters

- EU stock in Latvia for common OSRAM ST-class starters and HID igniters — frequent same-day dispatch within Europe.

- Audit-ready documentation (CE/EAC, conformity notes) delivered with each SKU for your procurement files.

- Cross-reference help: we map site lists (lamp W, ballast type, cable run) to the correct OSRAM starter/igniter families.

- Consolidated B2B shipments: lamps, ballasts, starters/igniters in one PO to cut freight and admin time.