Nowodvorski Cable bearing systems

Nowodworski Cable Trays for Industrial and Commercial Installations

In large-scale installations — from data centres and manufacturing halls to infrastructure projects — structured routing of power, control and communication cables is a critical part of system reliability. Nowodworski cable trays provide a rigid support framework rated for both heavy duty and standard duty loads. When specifying, you should check load rating (e.g., 50–300 kg/m span), material (galvanized steel, stainless or pre-painted), width (100–600 mm typical) and length (3 m sections common). Industry guidelines (e.g., Cable Tray Institute) emphasise fill ratios, support spacing and grounding for safety.

From an installation perspective: a well-specified tray system allows for future cable expansion, easier maintenance access, and avoids the bottlenecks of conduit systems where pulling new cables becomes difficult over time.

Nowodworski Wire-Mesh Trays & Installation Support Systems

For installations requiring high airflow (e.g., control rooms, switchgear halls) or frequent re-configuration, the Nowodworski wire-mesh tray variant is a practical choice. Mesh trays reduce heat buildup, allow cable visibility and branch access. Specifications to review include mesh spacing, cross-sectional area, span length and material finish (e.g., zinc or stainless).

Support structures — such as Nowodworski mounting channels, brackets and strut systems — matter equally. Proper support prevents sagging trays or mechanical fatigue (which are frequent in poorly designed frameworks). Design guidelines note that inadequate strut systems lead to misalignment and cable stress.

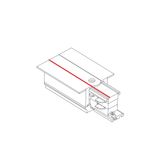

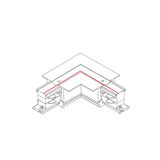

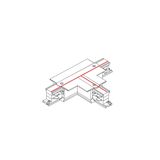

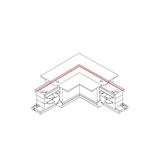

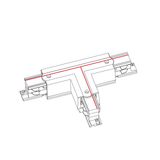

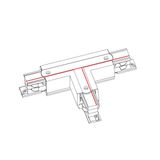

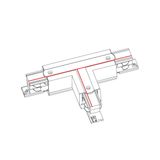

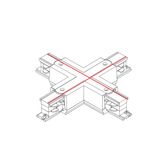

Nowodworski Routing Systems & Modular Blocks for Cable Management

Routing systems extend beyond horizontal trays. Nowodworski systems typically include modular routing channels, vertical risers, transition elbows, bus-bar compartments and support accessories. From a specification standpoint: evaluate compatibility of accessories, standardisation of widths and depths, provision for fire-sealing where trays pass fire-rated partitions (refer to NEC Article 392-style guidance in US but applicable conceptually).

In practice: specifying a full system from one brand (Nowodworski) gives you consistent mechanical interfaces, predictable spare-parts and simplified maintenance schedules rather than a mix of disparate suppliers.

Practical Selection Guidelines for Engineers & Buyers

Before placing a bulk order of Nowodworski systems, ensure you verify:

- Material & corrosion rating: e.g., hot-dip galvanised (> 55 µm zinc) for indoor, stainless steel (AISI 316) for harsh environments.

- Load rating & support span: check maximum cable weight per metre and span between brackets.

- Tray width/depth: sized not only for present cables but for 20-30 % future growth to avoid overfill

- Accessory compatibility: bends, tees, reducers, covers must match system.

- Grounding/earthing provision: ensure tray or system allows bonding as required by standards.

- Modularity & future changes: ability to add sections, branches or remove cables without disrupting existing runs.

Applications that skip one of these often encounter re-engineering, excessive modifications or increased labour costs during retrofit.

Why Standardising on Nowodworski Makes Sense

Choosing Nowodworski across your cable-routing architecture—from trays to mesh systems to support modules—yields operational advantages: uniform tooling for install teams, predictable stock of spares and accessories, simplified training, fewer supplier-interfaces, consistent mechanical and electrical performance. In high-scale projects these sync-benefits reduce install time, spares logistics and long-term maintenance burden.

B2B & Wholesale Supply Offer via Bank of Lamps

When procuring Nowodworski cable-bearing systems through Bank of Lamps, you gain project-scale support and trade-oriented supply terms:

- Customised pricing based on project volume, repeat orders and multi-phase deliveries.

- A dedicated account-manager for Nowodworski routing systems, assisting with spec review, BIM families, accessory lists and delivery coordination.

- Live inventory checks across central and partner warehouses, reducing lead-time risk.

- Rapid quotation turnaround — most responses within one business hour, enabling tender deadlines.

- Ordering via EAN/MPN spreadsheets ensuring accuracy in multi-line procurement.

- Downloadable full documentation: CAD/BIM drawings, spec sheets, material certificates and cut-lists.

- Comprehensive logistics tracking from order confirmation through shipment and delivery.