Morek Industrial Automation

MOREK Automation Systems for Panel Builders and OEMs

When you design control panels, process cabinets or machine drives, selecting the right automation system is more than picking a PLC stack. The MOREK automation systems line focuses on modularity, serviceability and compatibility. In practice you’ll find base modules rated for typical panel supplies (24 V DC / 230 V AC), I/O counts to match control logic, and certified compliance (often IEC 61131-3 programming, UL/CE marking). Choosing MOREK systems means fewer split vendor interfaces, uniform documentation and predictable spare-parts management on maintenance cycles.

MOREK Control Modules – Signal, Power, Logic Interfaces

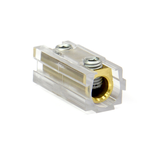

Under the term “MOREK control modules” you encounter signal converters, DIN-rail mounted relays, interface modules, bus-compatible I/O blocks and timer/relay units. For instance, their modules may handle conductor cross-sections up to 50 mm² in power distribution blocks, or carry signal conversion for control systems.

In real installations, technicians check:

- enclosure mounting type (DIN-rail, screw-mount)

- rated current/voltage (e.g., 10 A @ 230 V AC for logic relays)

- galvanic isolation between control and field side

- serviceability (replaceable modules)

If your panel houses multiple brand families, specifying MOREK control modules gives you a single supplier for spares and simplifies lifecycle logistics.

MOREK Switching Devices – Power & Logic Switching Elements

When your system requires actual switching — e.g., toggling power circuits, controlling loads or emergency functions — “MOREK switching devices” come into play. You’ll find compact power-switch modules, manual or motorised isolation switches, contactor blocks and smart switch gear. One example: the SD power-control switch rated up to 200 A, highest impulse voltage 8 kV under IEC 60947-1/3.

From installer experience: choosing correct switching device means size the device service current, check duty-cycle rating (frequent switching or few cycles), and select the right operator interface (manual lever vs motor drive). MOREK’s range has clear load-rating tags and standard footprints — that means faster replacements in field maintenance.

MOREK Control Accessories – Cabling, Connectors, Mounting Packs

The “MOREK control accessories” category covers everything around the logic modules and switches: terminal blocks, DIN-rail brackets, coded connectors, harness mounts and spare interface parts. These accessories decide how clean, maintainable and sustainable your cabinet wiring will become. For example, a pack of coded connectors that lock with correct polarity avoids mis-wiring during servicing. As one procurement lead put it: “the automation logic might last 15 years, but if the connectors are weird we spend two days fault-finding every service cycle.”

When specifying, check support documentation: are accessory parts cross-listed with module family codes? Are spares stocked? MOREK provides good traceability for these parts.

Practical Comparison – Modular Automation vs Traditional Fixed Logic

In many plants, the choice falls between fixed-logic switching (relays, timers) and full modular automation. Here’s how they compare:

- Fixed logic (timers, basic relays): lower cost, simpler wiring, very predictable. But when extension is required or central monitoring, they hit limits

- Modular automation (control modules + switching + accessories): higher upfront cost, more complex design, but scales far more easily, allows remote diagnostics, reduces re-wiring when functions change.

From integrator feedback: if your expected system life is > 10 years or you expect expansions, investing in MOREK modular automation pays off in faster upgrades and lower “change-order” time. If it’s a simple machine with short lifecycle, fixed logic may still work—but you risk being obsolete sooner.

Buyer Checklist & Specification Guidance

- Confirm rated inputs/outputs: voltage (24 V DC vs 230 V AC), current rating, switching frequency.

- Verify connectivity and bus support: fieldbus (Profibus, EtherCAT) or traditional hard-wired? MOREK modules often support standard bus interfaces.

- Assess standards compliance: IEC 61131 for programming, IEC 60947 for switching devices, UL/CE for export.

- Check physical footprint and mounting: DIN-rail vs panel cut-out; spacing for ventilation; service clearance.

- Plan for spares and life-cycle: Are spare modules, connectors, accessories available in your region? Stocking 10 % spares of key modules often prevents prolonged downtime.

- Understand accessories compatibility: Using a single brand like MOREK for modules and accessories simplifies training, labels, spares.

Common mistakes: mixing vendor logics means dual spare-stocks; undersizing switching device for actual load; ignoring accessory lead-times (those smaller items often stop you dead when missing on site).

Wholesale Supply & Strategic Partnership with Bank of Lamps

Bank of Lamps distributes the full MOREK Automatics and Control range across Europe from our central Latvian warehouse. We work with OEMs, panel-builders, system integrators and electrical wholesalers who need standard part numbers, repeatable supply chains and documentation support for large projects.

Why Choose Bank of Lamps

- Tailored B2B pricing aligned with your project framework and repeat volumes.

- Dedicated account manager covering both technical and commercial aspects.

- Ral-time stock visibility across our warehouse and partner networks.

- Quotation turnaround typically within one hour for standard product lists.

- Ordering via EAN/MPN lists for precise processing and quick assembly.

- Downloadable and up-to-date price-lists for procurement departments.

- Transparent lead-time tracking: know when modules, switches, accessories move from factory to your site.

- Access to full purchase history to simplify repeat orders and project budgeting.

Deferred payment options (up to 30 days) for approved clients working on large systems.