Legrand Junction Boxes

BATIBOX MACONN.2POSTES P.40MM

BATIBOX MACONN.4POSTES P.40MM

BOITE DE DERIVATION 155X110 ERP

BTE CL.SECHE D.67 3P VERT.P50

COUVERCLE POSE REDUCTEUR D.60

BOITE BETON DERIV.303X195X92

RECTANGULAR PLEXO BOX

BOITE DE DERIVATION D.60 PLEXO

BOITE RONDE D.85 PROF.40

CROCHET BATIBOX RILSAN L.120MM

BOITE CLOISON SECHE D.85 PROF.40

FLUSH MOUNTING BOX 3 MODULES

COUVERCLE BATIBOX BOITE 2X6/8M

COUVERCLE BATIBOX BOITE 2X4/5M

BATIBOX MACONN.PC 32A P.40MM

Legrand Installation Boxes – Reliable Building Blocks for Electrical Systems

The Legrand installation boxes form the foundation of any wiring system. Whether you’re dealing with new-builds or renovations, these boxes house connections, switches, outlets, and ensure that cables are safe, accessible and code-compliant. Legrand markets a full line of electrical boxes made from durable thermoplastic or metal, designed to cut install time and reduce callbacks

In practice, specifying Legrand installation boxes means choosing from a known brand, consistent parts across jobs, and simplifying maintenance downstream. If your contractor uses different brands for boxes, fittings and supports, you end up managing more SKUs and potential mismatches.

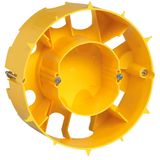

Legrand Flush Mounting Boxes – Clean, Integral Installations

When the aim is a flush, invisible finish in drywall or masonry, the Legrand flush mounting boxes are the right choice. These boxes are designed for “old work” or new construction, feature quick-mount brackets or swing clips, and maintain the correct depth for trim plates and switches.

From an installation viewpoint: select the correct gang size (single, double, triple), check the knock-out count, and ensure the box material suits the environment (thermoplastic for non-metallic conduit, steel for metallic). Boxes pre-integrated with auto-clamps or adjustable depth are particularly helpful in fast-turn projects.

Legrand Surface Boxes – Flexible Mounting for Retros & Renovations

For surface wiring, exposed conduits or renovations where in-wall mounting is impossible, the Legrand surface boxes provide robust support. These boxes are used on concrete, brick or existing walls, often with screw or anchor fixings rather than being built into the wall.

As a procurement note: surface boxes allow you to minimise wall cut-outs, speed up installation, and reduce dust or disruption — especially relevant in occupied buildings or retrofit scenarios.

Legrand Electrical Enclosures & Junction Boxes – Larger-Scale Infrastructure

In commercial, industrial or multi-unit residential builds you’ll often specify the Legrand electrical enclosures / junction boxes for aggregating wiring, protecting terminations and enabling service access. These might be flush or surface mount, modular or fixed size, and must meet mechanical and electrical ratings (IP, IK, material).

For specification: verify knock-out patterns, load capacity, fire rating, accessibility for maintenance, and compatibility with downstream device housings. Using Legrand enclosures across a project simplifies parts lists and ensures consistency in service contracts.

Legrand Modular Installation Boxes – Scalable & Standardised Systems

Standardisation is valuable when rolling out multiple units or buildings. The Legrand modular installation boxes let you use the same box size, cover plates and accessories across a series of rooms or floors, reducing logistics complexity and inventory variety.

From a maintenance / lifecycle viewpoint: fewer SKUs, same brand for box and cover means fewer surprises when replacements are needed. Future-proofing becomes simpler if you design on one brand this early.

Buyer Checklist & Practical Recommendations

- Material & mounting type: Thermoplastic vs steel; flush vs surface; “old work” vs new work.

- Gang size & knock-outs: Select based on how many devices go into the box and conduit entries.

- Depth & cover compatibility: Ensure box depth suits wall finish and that cover plate aligns.

- Environmental ratings: For exposed or wet areas choose boxes/enclosures with appropriate IP/IK ratings.

- Logistics & stock: Using one brand across boxes, enclosures, covers simplifies procurement and spares.

- Common mistakes to avoid: Mixed brands causing incompatibility, selecting box too shallow for device depth, inadequate knock-outs slowing cable entry.

Wholesale & B2B Supply — Bank of Lamps

For electricians, contractors and wholesale distributors, the Legrand installation boxes category offers a strong value proposition.

Bank of Lamps supplies the full range of Legrand installation boxes, enclosures, surface and flush mounting systems with:

- Volume pricing for projects and rolls-outs.

- Full product documentation and datasheets (gang sizes, materials, depth, knock-outs).

- Logistics and dispatch across Europe (including Ukraine).

- Support with specification: ensuring correct box type, mounting method and accessory covers.

If you’re sourcing boxes and enclosures for large installations, renovation projects or multi-site roll-outs — specifying Legrand installation boxes reduces part variance, streamlines maintenance and improves installation consistency.