LEDVANCE Fluorescent Tubes

Place of LEDVANCE Fluorescent Tubes in the Portfolio

LEDVANCE is best known today for LED lamps and luminaires, but it still maintains a focused range of LEDVANCE fluorescent tubes for T8 and T5 installations that are still in service. These lamps are largely the continuation of the old OSRAM/LEDVANCE “LUMILUX” and “Basic” linear fluorescent families, rebranded and streamlined rather than completely reinvented. Fluorescent tubes remain a practical solution for facilities that rely on broad, uniform lighting and predictable maintenance intervals. In environments where colour stability and consistent lumen output are essential — such as classrooms, laboratories and specialised work areas — planners often start with proven, high-reliability options like narva fluorescent tubes. For routine replacements across mixed-use buildings, maintenance teams frequently turn to compatibility-focused, easy-to-stock ranges such as leuci fluorescent tubes. Commercial interiors and infrastructure projects requiring tighter electrical conformity or higher-grade components sometimes incorporate specialised, system-oriented products like legrand fluorescent tubes. Public facilities, offices and budget-driven refurbishments often rely on straightforward, service-friendly lighting options such as kanlux fluorescent tubes to keep maintenance predictable. And for large portfolios where global availability and long-term consistency matter, specifiers frequently complete their lighting sets with the universally recognised, stable-performance ranges offered by ge fluorescent tubes.

In real projects, LEDVANCE fluorescent tubes are used to:

- keep existing T8 and T5 luminaires running safely and legally,

- give a brand-backed, spec-grade alternative to anonymous no-name tubes,

- bridge the gap until a full LED upgrade (often with SubstiTUBE LED replacements or new LEDVANCE luminaires).

So you can treat LEDVANCE Fluorescent Tubes as the “serious, documented” option for legacy linear fluorescent systems.

Technology and Construction of LEDVANCE Fluorescent Tubes

Most LEDVANCE Fluorescent Tubes are conventional low-pressure discharge lamps using mature, proven tech:

- Tube formats

- T8 – 26 mm diameter, G13 caps, in standard lengths (15/18/30/36/58 W classes, depending on region).

- T5 – 16 mm diameter, G5 caps, in HE (High Efficiency) and HO (High Output) variants for slim, modern luminaires.

- Internal build

- Coiled tungsten cathodes at each end.

- Low-pressure inert gas plus a small amount of mercury to generate UV.

- Triphosphor coating for good colour rendering and efficiency.

- Light quality

- Typical CRI around 80 for standard LUMILUX-type tubes – suitable for offices, shops and industry.

- Common colour codes:

- 830 – 3000 K warm white,

- 840 – 4000 K neutral white,

- 865 – 6500 K daylight.

- Typical performance ranges

- Efficacy: roughly 80–95 lm/W depending on wattage and type.

- Lifetime: often 12,000–20,000 h nominal for T8 and 16,000–24,000 h for T5 HE/HO on proper electronic gear.

In other words, LEDVANCE Fluorescent Tubes behave exactly like you’d expect from a top-tier European linear fluorescent: stable colour, decent efficacy, and predictable lifetime.

Main Families and Assortment of LEDVANCE Fluorescent Tubes

Exact names differ slightly by market, but the range usually falls into a few clear lines.

T8 LEDVANCE Fluorescent Tubes

- LUMILUX-type T8 (tri-phosphor)

- 18 W / 26 mm / ~600 mm

- 36 W / 26 mm / ~1200 mm

- 58 W / 26 mm / ~1500 mm

- Colour codes 830, 840, 865.

These are the classic “office/retail/industry” tubes.

- Basic / value T8

- Similar wattages and lengths, slightly simpler specs, aimed at cost-sensitive maintenance where ultra-long life is not critical.

T5 LEDVANCE Fluorescent Tubes

- T5 HE (High Efficiency)

- 14, 21, 28, 35 W classes.

- Designed for maximum lm/W, used in slim recessed fittings and continuous-row luminaires.

- T5 HO (High Output)

- 24, 39, 49, 54, 80 W.

- Higher lumen packages for high ceilings, retail aisles and industrial spaces.

Together, these families let you maintain almost any “classic” T8/T5 LEDVANCE or OSRAM-based luminaire without changing the fixture.

Typical Applications of LEDVANCE Fluorescent Tubes

Because they are standard T5/T8 formats, LEDVANCE Fluorescent Tubes show up in a wide variety of luminaires:

- Retail and supermarkets

- T8 36 W and 58 W tubes in trunking systems and modular ceilings.

- T5 HE/HO in narrow linear systems over aisles and shelving.

- Offices, schools and public buildings

- T5 HE in recessed grid luminaires and slim suspended fittings.

- 3000 K or 4000 K depending on design intent and regional preference.

- Industrial and logistics

- T5 HO (49–80 W) and T8 58 W tubes in IP65 battens and high-bay fittings where luminaires are still fluorescent.

- Corridors, stairwells, basements

- T8 15/18/36 W LEDVANCE Fluorescent Tubes in simple strip lights, ceiling battens and wall lights, chosen for reliability and one-brand sourcing.

In most of these cases, the luminaires are mechanically fine and control gear still works; replacing old tubes with LEDVANCE Fluorescent Tubes restores proper light without a complete redesign.

How to Select LEDVANCE Fluorescent Tubes Correctly

Don’t just pick a wattage at random. A quick, systematic approach avoids problems.

1. Identify tube type and size

- Check if the fixture is T8 (26 mm, G13) or T5 (16 mm, G5).

- Read the old lamp and measure:

- ~600 mm → usually 18 W T8 or 14/21 W T5 depending on diameter,

- ~1200 mm → 36 W T8 or 28/35/54 W T5,

- ~1500 mm → 58 W T8 or 80 W T5.

T5 and T8 are not interchangeable – different diameter, base and ballast.

2. Match wattage and control gear

- Use the luminaire label as your main reference:

- “1 × 36 W T8” means you need a 36 W T8 LEDVANCE fluorescent tube.

- “2 × 49 W T5 HO” means exactly that – two 49 W T5 HO tubes.

- On magnetic gear, ballasts are tuned to a specific wattage. Wrong lamps can cause flicker, poor starting and overheating.

- T5 HE/HO must run on suitable electronic ballasts; they’re not designed for old starter-based circuits.

3. Choose colour temperature and CRI

Think about the space:

- 3000 K (830) – warm, comfortable; good for hospitality, residential-feel corridors and some retail.

- 4000 K (840) – neutral; the default for offices, schools, shops and many industrial spaces.

- 6500 K (865) – daylight; for workshops, QC labs, certain retail areas or where high visual contrast is needed.

Stick to one colour temperature per visual zone so rows of luminaires look uniform.

4. Consider lifetime and maintenance strategy

- In high-hour applications (10–16 h/day), plan group relamping before the very end of rated life – for example around 70–80 % of the nominal hour rating.

- For low-hour spaces (storage rooms, rarely used areas), spot replacement is usually enough, but still keep the same LEDVANCE type and colour to avoid patchy appearance.

Technical Performance and Design Use of LEDVANCE Fluorescent Tubes

From a planning point of view, LEDVANCE Fluorescent Tubes give you reliable design numbers:

- Typical luminous flux (order of magnitude)

- 18 W T8: ~1200–1350 lm

- 36 W T8: ~3200–3400 lm

- 58 W T8: ~5200–5500 lm

- 28 W T5 HE: ~2600–2800 lm

- 54 W T5 HO: ~4450–5000 lm

- Lifetime

- Standard T8: 12,000–20,000 h depending on series and ballast.

- T5 HE/HO: often up to 24,000 h on electronic ballasts with good switching patterns.

- Lumen maintenance

- Quality tri-phosphor tubes usually retain 80–90 % of initial flux through most of their rated life if operated on correct gear and temperature.

When designing or checking an installation, you can use these values to calculate approximate lux levels and decide whether to replace like-for-like, increase lamp count, or switch to LED.

Safety, Ballasts and Environmental Aspects

Even with a reputable brand, fluorescent rules still apply to LEDVANCE Fluorescent Tubes:

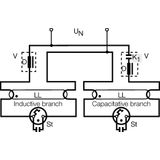

- Correct gear

- Never connect fluorescent tubes directly to mains – they need a ballast.

- On magnetic gear, use correct starters; on electronic gear, check compatibility with T8/T5 and dimming where relevant.

- Thermal limits

- Don’t exceed the luminaire’s rated lamp power. Over-lamping stresses ballasts, lampholders and plastics.

- Keep diffusers and housings fairly clean so heat can escape.

- Handling

- Always power off and isolate the circuit.

- Support the lamp with both hands near the ends, rotate gently in the lampholders until it locks – don’t twist against the glass.

- Mercury and recycling

- LEDVANCE fluorescent tubes contain a small amount of mercury. They must go into proper lamp/WEEE recycling, not general waste.

- Broken lamps should be cleaned up carefully, with ventilation and avoidance of direct contact with phosphor dust.

If you respect those basics, you’ll generally get the full advertised lifetime out of LEDVANCE tubes.

LEDVANCE Fluorescent Tubes vs LEDVANCE LED Solutions

LEDVANCE is strongly LED-focused today, so every fluorescent line has a natural LED counterpart:

- SubstiTUBE LED T8 and T5 – LED retrofit tubes for many existing fluorescent luminaires.

- New LED battens and trunking systems – complete luminaires that replace fluorescent gear entirely.

A sensible strategy:

- Use LEDVANCE Fluorescent Tubes where:

- the fittings are in good condition,

- control gear is healthy,

- run-hours are moderate, and

- budget or building constraints don’t justify a full LED conversion yet.

- Plan LEDVANCE LED upgrades where:

- burning hours are high (shops, logistics, 24/7 areas),

- ballasts are failing,

- or you need advanced controls (dimming, presence detection, tunable white).

By documenting which LEDVANCE Fluorescent Tubes are in use (type, wattage, CCT) and which LED alternatives match their light output, you get a clean migration path: today’s maintenance stays straightforward, and tomorrow’s retrofit is based on concrete, known reference values instead of guesswork.