LAPP Cable bearing systems

-

-

1

- 2

-

The LAPP cable bearing systems range supports comprehensive cabling infrastructure for industrial, commercial and infrastructure projects — including lapp cable trays and ladders, lapp wire mesh trays, lapp support systems, lapp cable routing systems, and lapp tray accessories — all under the umbrella of lapp cable bearing systems. Whether you’re designing a high-capacity cable run in a data centre, routing power/control cables above a plant floor, or installing a structured cable route in an infrastructure environment, LAPP’s offering provides robust mechanical support with system-compatibility.

Keywords: lapp cable bearing systems, lapp cable trays and ladders, lapp wire mesh trays, lapp support systems, lapp cable routing systems, lapp tray accessories.

Full Range of Cable Tray & Support Solutions

Within this category you’ll find:

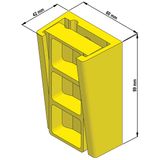

- Cable trays and ladders – ladder-type trays, ventilated trays, solid-bottom trays and heavy-duty cable-ladder systems designed for large bundles of power and control cables.

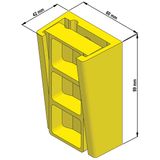

- Wire mesh trays – mesh-type cable routing trays (also known as basket trays) ideal for flexible routing, branch-offs and retrofit environments.

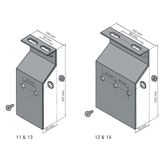

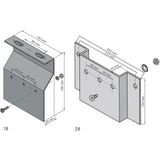

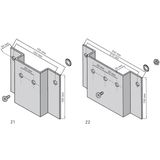

- Support systems – brackets, cable tray supports, cantilever arms, hangers and wall/ceiling supports designed to fix cable tray systems securely.

- Cable routing systems – complete pathways for cable management, including horizontal and vertical runs, tray routing, ladder systems, transitions, and dedicated routing systems for high-density wiring.

- Tray accessories – end-caps, covers, dividers, drop-outs, splice plates, cable fixes, and accessories that enhance installation safety, segregation and maintenance.

By selecting LAPP full-system support from tray to fixings, you reduce interface risks, ensure mechanical integrity and enhance system reliability.

Trays & Ladders – Technical & Practical Highlights

Types & Considerations

Cable ladder systems (which are a subtype of cable tray) are used where large cable bundles need strong support and good ventilation. According to generic definitions: “A cable tray is a unit or assembly … used to securely fasten or support cables and raceways.”

Wire mesh trays (basket trays) are lighter, more flexible in routing and good for data/telecom or retrofit wiring.

Design Considerations

When specifying, important criteria include:

- Load-rating of tray/ladder (weight of cables + future growth)

- Span lengths & support spacing

- Material & finish (galvanised, stainless, aluminium) for corrosion/indoor/outdoor use

- Ventilation vs solid-bottom for heat dissipation

- Compatibility with cable clamps/dividers to ensure separation of power/control/data circuits for EMC and fire safety.

LAPP Support System Features

While LAPP’s catalogue focuses more on cable management, ducts and trays, it signals competency in “cable management systems… tools & accessories” for fastening and inserting cables.

For example: LAPP offers cable duct and fastening clamp systems capable of being integrated with tray supports.

Practical Tip:

For a plant floor installation: choose a cable ladder system for power/large bundles, ensure bracket spacing meets load, choose galvanised finish if humid or chemical environment, and include splice joints and covers to maintain mechanical integrity. Add wire mesh tray branches for instrumentation/data cables off the main tray run.

Wire Mesh Trays & Routing Systems

Wire mesh trays from LAPP or compatible systems support flexible cable routing:

- Ideal for high-density signal/data areas, retrofit wiring, building services.

- Easier to change, drop cables, re-route compared to solid trays.

- Combine with tray accessories: covers, drop-outs, dividers for signal/power segregation.

Routing Systems & Accessories

Tray accessories (end-caps, covers, dividers, drop-outs) help maintain safety, prevent cable damage, allow segregation of different cable types (power vs data).

Support systems (brackets, hangers) ensure the routing is mechanically fixed and compliant with building/cable standards.

Why Choose LAPP Cable Bearing Systems?

- One-brand system: Using LAPP or fully compatible tray and support systems means specification consistency across cables, routing infrastructure and mounting.

- Industrial-grade reliability: The emphasis in LAPP’s product statements on “cable management systems … for fixing and inserting cables” shows they cover support hardware, not just cables.

- Future-proof infrastructure: With modular tray ladders, wire mesh routing and full accessory sets, installations can be expanded or changed without ripping out major parts.

- Procurement & maintenance efficiency: For electrical contractors, panel builders or installation firms, standardising on a full system supplier reduces SKUs, simplifies logistics and streamlines maintenance.

Wholesale & Project Distribution

At Bank of Lamps we supply the full LAPP cable bearing systems range — covering cable trays and ladders, wire mesh trays, support systems, cable routing systems and tray accessories. We support B2B orders, project-scale quantities and logistic distribution across Europe (Germany, Netherlands, France, Spain, Baltics, UK).