Kanlux Switches and sockets

KANLUX Switches and Sockets Built for Real-Site Reliability

In any project — whether it’s a residential block, hotel renovation or light industrial facility — the small details define system reliability. KANLUX switches and sockets are engineered as functional components, not décor. Contact groups use silver-nickel alloys rated for 10–16 A continuous load, meaning stable conductivity and lower wear during frequent switching. The housings are made of impact-resistant, flame-retardant thermoplastic that maintains its rigidity under heat, making KANLUX a safe choice for long-term installations in both private and public spaces.

KANLUX Modular Systems That Simplify Planning and Maintenance

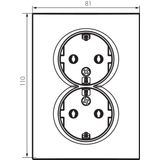

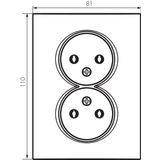

Electrical designers value flexibility. KANLUX modular switches and sockets allow multiple configurations in one frame — from single control points to four-module sets combining light switches, sockets, and data ports. The modular approach reduces stock variety and simplifies on-site assembly: one universal mechanism fits into different frame designs. Procurement departments benefit from unified ordering codes, while installers avoid the “missing part” problem during commissioning.

KANLUX Wall Switches Designed for Smooth Operation

Behind every click is mechanical precision. KANLUX wall switches employ reinforced toggle mechanisms with tight spring feedback to prevent accidental contact bounce. Rated for 100 000 cycles, they remain consistent even in frequently used circuits such as corridors or staircases. The low-profile design aligns flush with the wall surface, and terminals accept solid or stranded wire up to 2.5 mm², giving electricians flexibility when wiring mixed cable types.

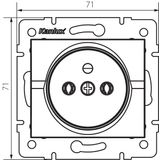

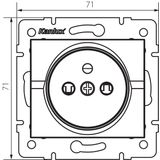

KANLUX Power Sockets That Combine Safety and Practicality

Current stability and grounding reliability are critical in modern facilities with sensitive electronics. KANLUX power sockets include child-protection shutters, brass terminals and corrosion-resistant contacts to guarantee firm plug retention and constant voltage delivery. The internal wiring layout minimizes heat buildup, making them suitable for continuous loads like computers, chargers or lighting controllers. All sockets comply with EU safety standards (EN 60669 and EN 60884), ensuring full compatibility with European plugs and frames.

KANLUX Decorative Sets That Align with Interior Design Standards

Functionality doesn’t exclude aesthetics. KANLUX decorative switch and socket sets come in matte, glass, or brushed-metal finishes, allowing architects to match them with wall textures, fixtures, and lighting. The frame and mechanism remain the same as in the professional line — only the surface design changes. This means an entire building can use one electrical system while offering different visual styles for premium areas and back-office zones.

KANLUX Flush Mounted Accessories That Keep Surfaces Clean

Precision mounting saves hours of finishing work. KANLUX flush-mounted accessories ensure seamless integration into drywall, plaster or concrete surfaces. Installation claws and leveling brackets allow quick positioning before plastering, reducing misalignment risk. The result is a perfectly level switch or socket faceplate that sits tight, without visible gaps or wobble — a small but crucial detail in any professional installation.

KANLUX Installation Frames That Guarantee Compatibility

Every modular system depends on the base. KANLUX installation frames maintain mechanical stability and exact spacing between modules. Made of reinforced polyamide, they resist deformation during plastering or tightening. Multi-frame configurations (1 × 2 up to 1 × 5 modules) enable consistent alignment across entire wall lines. Using original KANLUX frames ensures that faceplates lock precisely without tension — a common cause of cracked glass and misaligned panels in mixed-brand setups.

Why Contractors Source KANLUX Through Bank of Lamps

At Bank of Lamps, we deliver the complete KANLUX switch and socket range from our central EU warehouse in Latvia. Our logistics system supports both project bulk orders and regular replenishment for electricians and distributors. Each product batch includes CE certification, wiring diagrams and mounting documentation. For procurement managers, that means predictable delivery and long-term availability; for installers, consistent components that assemble faster and perform longer — the foundation of reliable electrical infrastructure.