Kanlux High bay

HIBO LED N 100W-NW

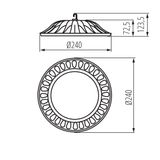

HIBO LED N 50W-NW

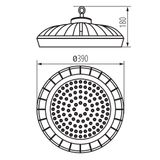

HIBO LED N 150W-NW

HIBO LED N 200W-NW

KANLUX Highbays for Industrial and Warehouse Lighting

Real Output and Consistency in Demanding Facilities

Every engineer knows the problem: a 12-metre warehouse ceiling, dust in the air, heat from machines — and lights that lose 30 % brightness in a year. KANLUX highbays are built for these exact conditions. Their LED modules maintain over 90 % lumen retention after 50 000 hours, even under 45 °C ambient temperature. Aluminium housings work as passive heat exchangers, pulling heat away from the diodes to keep colour stability at 4000 K throughout their lifetime.

Efficiency Measured in Numbers, Not Promises

Switching from 400 W metal-halide to a 150 W KANLUX LED high bay light saves around 60 % in energy, translating into roughly €350 per luminaire per year for a 24/7 plant. Multiply that by 200 fixtures — and your annual savings exceed €70 000 without compromising visibility. Power factor above 0.95 keeps electrical balance stable across phases, which matters when circuits feed heavy industrial equipment.

Compact KANLUX UFO Models for Fast Installation

Mounting on 10-metre trusses takes time, and labour costs often exceed fixture cost. KANLUX UFO highbays weigh under 4 kg and mount with a single M10 hook or bracket. Each unit includes quick-connect wiring and pre-aligned optics (60°, 90°, 120°) — installers simply choose the beam angle that fits the floor layout. That precision reduces wasted light and improves lux-to-watt ratio by up to 15 %.

Built to Survive the Real World

Industrial lighting fails not because of LEDs, but because of moisture, dust and vibration. KANLUX industrial highbay luminaires are rated IP65, sealed with silicone gaskets and impact-resistant lenses. Drivers use 4 kV surge protection and double insulation, meaning less downtime after grid fluctuations. In food-processing zones, polycarbonate diffusers withstand cleaning chemicals; in steel plants, temperature-rated seals prevent condensation damage.

Uniform Light for Safe and Productive Work

Visibility defines productivity. KANLUX warehouse highbay lighting provides CRI > 80 and uniformity ratio over 0.7, so workers distinguish labels and surfaces correctly. Proper optical control eliminates glare zones — critical for forklift operators who navigate reflective aisles. Optional 1–10 V or DALI dimming lets automation engineers integrate lighting with motion sensors or daylight tracking, reducing unnecessary power draw during idle periods.

Accessories That Make Installation Predictable

KANLUX mounting accessories for highbays — suspension cables, brackets, safety chains — share load ratings equal to or higher than the luminaire weight by a 5× factor. Using original accessories preserves certification and guarantees correct heat dissipation spacing above the housing. For facilities with vibration, such as stamping or packaging lines, rubber-isolated mounts reduce stress on ceiling points by 30 %.

Integrated Systems for High Ceilings

In plants with ceilings over 14 m, traditional spacing creates dark zones. KANLUX high ceiling LED fixtures use multi-chip arrays delivering up to 28 000 lm, allowing fewer units per square metre and reducing circuit load. The modular design supports daisy-chain power connection up to 10 units on one line, simplifying wiring and inspection.

Reliable Supply Through Bank of Lamps

Bank of Lamps provides the complete KANLUX highbay portfolio across Europe from our central warehouse in Latvia. Each product comes with datasheets, photometric diagrams, and batch traceability. We support bulk procurement, low-MOQ samples for pilot projects, and regular stock for service teams. For contractors, that means fast replacements; for procurement managers, a stable pricing structure and delivery cycle measured in days, not weeks.