IFM electronic Electric box (breaker panel)

ifm Electronic Distribution Boards are the Backbone of Industrial Control Systems

When you’re specifying distribution boards, electrical enclosures or modular panels as part of an automation or control installation, you’re not just buying a box. You’re choosing the framework for power, signal, safety and serviceability. ifm electronic distribution boards, switchgear cabinets and modular panels deliver brands, mechanics and logistics that are built for real industrial deployments. In practice you’ll usually see these enclosures in machine control rooms, factory panel lines, OEM switchgear sets and major automation systems where reliability and maintainability matter.

ifm Electrical Enclosures and Modular Panels What the Category Actually Includes

From experience working with multiple machine builds and control panel installs, the “distribution board / enclosure” category covers:

- Metal or polymer enclosures rated for industrial use, housing breakers, PLCs, relays and cabling. For example ifm lists “distribution box” models such as EBC010 and EBC020.

- Modular panel solutions and switchgear cabinets where standardisation of cut-outs, DIN rail mounting and wiring practices matter. ifm provides operating-panel modules and enclosures for machine control.

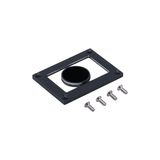

- Accessories and installation hardware for enclosures: mounting sets, wiring entries, busbar kits, knock-out panels, sealing kits. These are often overlooked but crucial.

For procurement and installation logic this means you’re ordering more than “just a cabinet”. You’re acquiring the physical structure that holds your system, manages wiring, allows servicing and supports future expansion.

Technical and Procurement Considerations That Matter for Distribution Boards and Enclosures

Based on real site work, here are key parameters and buying logic you should use:

- Rated enclosure size and module capacity: Determine number of modules or DIN rails you’ll need (for example, 24 or 48 ways), the space for cables, controllers and future expansion.

- Ingress protection, material and mounting style: Is the enclosure in a machine room (IP54-65) or outdoors/exposed zone (IP66 or above)? Choose weather- and dust-resistant versions.

- Heat management and ventilation: Many control panels generate heat. Ensure the enclosure supports ventilation or heat dissipation. The choice of enclosure size and material affects longevity of components inside.

- Mounting and accessibility: Does the cabinet allow easy access for wiring, test modules and replacements? If not, service time is extended.

- Standardisation of panel dimensions and cut-outs: If you standardise size and layout across panels (one brand, one module size, one enclosure family) you reduce SKUs, simplify spares and ease training.

In fact, you’ll usually see delays when enclosures arrive that don’t match controller layout, when cabling is forced into too small a box, or when service access is blocked. By specifying properly you avoid these issues.

Buying Logic for Wholesale Orders of ifm Distribution Boards and Cabinet Systems

As a procurement manager ordering these enclosures and panel systems in volume, apply this strategy to make your supply chain efficient:

- Select core enclosure families: Pick one or two sizes (e.g., medium 400x600 mm and larger 800x1000 mm) that cover the majority of your installations.

- Standardise finishes and mounting configurations: Choose one finish (e.g., light grey RAL7035) and uniform mounting style so field engineers recognise them instantly.

- Order spare enclosures and accessories: Panels may require replacements or retrofits—keeping spare enclosures, door hinges, cable entry kits reduces downtime. A common buffer is ~10% of unit count.

- Bundle with accessories and wiring kits: Since enclosures often come without wiring or accessory kits, order mounting plates, busbar sets or cable ducts at same time.

- Track part numbers and batch codes: Use manufacturer’s part codes (as ifm provides) for repeat orders, ensure shipment aligns across batches to avoid finish or product variation.

With this logic you'll reduce installation delays, simplify warehouses, and improve field team efficiency.

Why ifm Distribution Boards and Enclosures Make Sense for Industrial Projects

When you deploy across multiple machines, production lines or sites, consistency really pays off. Using one brand for enclosures and distribution boards (like ifm) gives you fewer suppliers, uniform installation logic, consistent documentation and spare-part alignment. For procurement that means fewer SKUs and predictable supply. For installers it means familiarity across panels. For maintenance it means easier service logistics. Over time this choice reduces cost, speeds commissioning and helps serviceability.

Wholesale Supply Partner – Bank of Lamps

Bank of Lamps supplies the full ifm distribution board / enclosure system portfolio — electronic distribution boards, electrical enclosures, switchgear cabinets and modular panels — from our warehouse in Latvia. We serve procurement teams, OEM panel builders and automation contractors across the UK, Germany, Netherlands, Baltic States, France, Spain and Belgium.

Our wholesale advantages include:

- Flexible bulk quantities tailored to project size – from singles to pallet loads.

- Verified brand-authentic ifm stock – no grey-imports, full complement of enclosures and accessories.

- Centralised EU logistics hub, which simplifies shipping across European countries and reduces customs delay.

- Stable wholesale pricing for framework orders and repeat projects.

- Full batch traceability, technical support, documentation (CAD models, datasheets) and supply-chain assistance.

Working with Bank of Lamps means you’re not just buying cabinets — you’re partnering with a supply-chain built for industrial-grade panel build reliability and procurement efficiency.