FINDER Switches

Finder Switches – Finder Wall Switches and Finder Modular Switch Systems

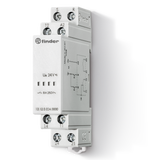

When you’re wiring control panels, operator stations or machine enclosures, the humble switch often determines whether the job finishes clean or comes back later. The category Finder switches (wall switches, modular switches, industrial switches, toggle switches, smart switches, switch systems) covers the parts that don’t get noticed—until they fail. Installers and procurement folks know: you want a switch that fits first time, wires cleanly, and won’t wobble or drift under use.

Technical Characteristics of Finder Modular Switches and Finder Industrial Switch Systems

- Rated voltage: standard units handle 230 V AC; industrial versions may support 400 V AC three-phase systems, depending on design.

- Current and switching capacity: typical modules rated for 10–16 A, some heavy-duty versions handle higher loads or mixed signal types.

- Mounting and footprint: modules designed for DIN-rail or flush wall mounting; same cut-outs across single/double/triple versions to simplify panel build.

- Terminal connections: screw-type or spring-clamp terminals; supports both solid and stranded conductors; tight contact force reduces loosening under vibration.

- Protection and durability: IP44 or higher available for industrial zones; impact-resistant frames, consistent actuator feel even after tens of thousands of cycles.

- Finish and modularity: frames in standard finishes (white, black, grey) with modular units behind; swapping modules later without changing the housing is possible.

From field experience: you can tell when the switch feels “cheap” — loose plate, uneven mount, wires shifting. Standardising on one family like Finder means you avoid that.

Practical Field Applications of Finder Wall Switches and Switch Systems

On a recent machine-build project: operator panels needed a consistent look for switches and controls. We used Finder wall switches across all panels—same actuator feel, same frame colour, same terminal layout. That meant commissioning went faster, maintenance later found spares easily.

In a factory retrofit: lighting and local machine isolation switches were replaced with Finder modular switches. Because the modules used the same frames, installers didn’t have to recut panels or adjust depth. We finished zones ahead of schedule.

In a dynamic workstation environment: smart switch modules (for communication or signalling) were part of the Finder switch systems. The service team appreciated that replacement modules had the same connectors and mounting as legacy ones—less downtime, fewer surprises.

Procurement Insights for Finder Switchgear and Switch Systems

For procurement and project managers ordering these in volume, several factors matter:

- Family standardisation: pick one module family for wall switches, modular switches and industrial units—reduces spare-stock variation.

- Cut-out & footprint consistency: ensure the same depth, frame size and mounting pattern so installers don’t need to adapt for each variant.

- Packaging & MOQ: switches may ship in cartons of 10-20 units; for large build-outs check for bulk-pack or tray options.

- Stock availability & lead times: standard modules should be in stock; custom finishes or smart versions might have longer delivery—time procurement accordingly.

- Service strategy: spares for 5-10 years matter. Buying a switch system you know will be available later avoids downtime during a rebuild or expansion.

From procurement logs: delays often come when switch finishes don’t match or modules require adapting frames—stick to one system like Finder and avoid those mis-orders.

Integration and Maintenance of Finder Switch Systems

When building panels or operator stations, the switch is one of the last items before wiring closes up. With modular systems like Finder’s, replacement or upgrade is straightforward: same frame, same actuator, just swap module. For maintenance crews that’s gold: they don’t need to re-wiring or re-panel. After years of vibration and temperature changes, a consistent switch tunnel means fewer service visits. If you standardise now, future expansions or replacements drop in simple and fast.

Why Contractors Source Finder Switches via Bank of Lamps

At Bank of Lamps we carry the full Finder switches and modular systems range from our central European warehouse (Latvia), shipping to the UK, Germany, Netherlands, Baltics, France, Spain and Belgium.

What makes us different:

- Real-time stock of standard and smart switch modules under one roof.

- Mixed-brand consolidation: switches, modular systems, control gear all in one order; less logistics complexity.

- Batch and traceability documentation included—ideal for panel assembly records.

- Flexible order sizes: small replacement units or large build-out pallets.

- Support from a team that knows install schedules, panel build logistics and deadlines—not just part lists.

When your build schedule says “switches in this week, wiring next week, commissioning after”, you need supply that delivers on time and fits straight out of the box. That’s what we aim for.