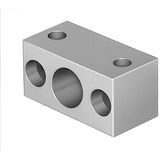

FESTO Electrical Installation

YSRF-25 Mounting flange

YSRF-32 Mounting flange

YSRF-16 Mounting flange

YSRF-8 Mounting flange

YSRF-12 Mounting flange

DAYH-5 Reducing sleeve

DAYH-4 Reducing sleeve

DAYH-10 Reducing sleeve

YSRF-20 Mounting flange

DAYH-8 Reducing sleeve

DAYH-7 Reducing sleeve

Festo Installation – Festo Mounting Systems and Industrial Installation Components

Every control cabinet or pneumatic line starts with the same question: how do we mount it so it stays in place for years? That’s where Festo installation hardware steps in — brackets, plates, and fixings that carry the real load in industrial systems. Engineers know that the wrong mounting system costs more in rework than the module it holds. Festo mounting systems and accessories make installation predictable: rails line up, holes match, clamps stay tight. For installers and procurement teams, this is not about design flair — it’s about mechanical discipline.

Technical Characteristics of Festo Installation Components and Mounting Hardware

- Construction materials: zinc-plated steel, aluminium, or stainless-steel grades for damp or corrosive areas.

- Mounting design: DIN-rail, base-plate or modular tie-rod systems compatible with Festo valve terminals and electrical units.

- Mechanical load capacity: engineered to absorb vibration and impact in industrial automation setups.

- Dimensions and tolerance: standard hole patterns and bracket spacing for seamless panel layout

- Surface finish: anti-corrosion coatings for long service life in dust, oil or chemical environments.

- Installation speed: most brackets pre-drilled, allowing quick mechanical assembly with minimal tools.

- Ambient conditions: operational temperature range typically –20 °C to +70 °C; ideal for production lines and machine panels.

Every millimetre matters in a control cabinet. One misaligned bracket, and you’ll spend an hour chasing bolt holes. These accessories eliminate that waste.

Practical Field Use of Festo Industrial Installation Hardware

In real installations, time is the currency. One project in an automotive line used modular Festo mounting systems for valve terminals. Fitters fixed forty brackets in a day — no drilling, no layout correction. The rail slots matched perfectly; everything aligned first go.

On another site, a bottling plant retrofit, the team used stainless Festo installation components to mount pneumatic manifolds above wash zones. The hardware survived humidity, detergent, and daily cleaning without corrosion or slippage. The same mounting logic applied in an electronics factory — installers used compact tie-rod systems to secure pressure regulators in a crowded control rack. Months later, nothing shifted under vibration.

Truth is, the installation hardware decides how often you come back to fix your own work. Good mounting gear saves service calls.

Procurement Considerations for Festo Installation Accessories and Components

From a purchasing desk, the questions are always the same:

- Compatibility: confirm bracket series matches valve or manifold footprint before shipment.

- Material selection: galvanised steel for dry zones, stainless for wet or corrosive areas.

- Packaging and MOQ: brackets often boxed in sets of 10–20; bulk orders palletised for easy warehouse tracking.

- Documentation: Festo hardware arrives labelled with part numbers and QR batch IDs — simplifies traceability for audits

- Delivery timing: mounting systems are critical-path items; missing rails can delay panel wiring by days.

- Cost vs labour: spending a few extra euros on proper brackets can cut total install hours by 20 %.

Procurement teams that standardise on one hardware family avoid mismatch chaos — and installers notice when everything fits out of the box

Integration and Maintenance of Festo Electrical Installation Systems

In control cabinets, space is tight. You need mounting hardware that lets you remove or add components without dismantling the frame. Festo systems are modular: unscrew one clamp, replace the module, lock it back in. No re-alignment. That’s what makes them popular among integrators who handle high-mix, low-volume assembly.

Maintenance teams also appreciate predictability. Once the mechanical base is set, adding new valves or I/O modules during expansion doesn’t require fabricating new plates. Same rails, same bolt patterns, zero redesign

Why Industrial Buyers Choose Festo Installation from Bank of Lamps

At Bank of Lamps, we don’t just move boxes — we keep automation moving. Our central warehouse in Latvia carries the full range of Festo installation components, ready for dispatch to partners across the UK, Germany, Netherlands, Baltics, France, Spain, and Belgium.

What sets us apart:

- Continuous EU-stock rotation for both electrical and pneumatic mounting systems.

- Ability to consolidate multi-brand hardware orders under one shipment — fewer suppliers, less paperwork.

- Predictable lead times matched to production schedules.

- Engineering-grade packaging built for export conditions.

- Technical staff who understand assembly realities and can match parts to your specific Festo modules.

When the build schedule is tight and the assembly line can’t wait, you need a distributor that delivers parts that fit and arrive on time. That’s what Bank of Lamps has built its reputation on.