Elektro-Plast Electrical Installation

Elektro Plast installation products form the physical backbone of wiring infrastructure. Their mounting systems, conduits, enclosures, and accessories protect cables, maintain routing discipline, and ensure safety and compliance. In any real project — residential, commercial, industrial — poor cable management leads to disorganized circuits, difficulty tracing faults, heat buildup, and code violations. Choosing the right Elektro Plast electrical installation components determines how clean, maintainable, and safe the final wiring layout will be.

Design Logic and Technical Construction of Elektro Plast Mounting Systems

Elektro Plast’s installation systems rely on several core design principles:

- Rigidity and dimensional stability: Channels, slats (CTS), and ducts are made of durable PVC or halogen-free plastics that resist warping under load or heat.

- Modularity and interconnectivity: Fittings—corners, couplers, connectors—match base components so installers easily extend or branch runs without special tooling.

- Flame retardance and material safety: Many systems employ halogen-free or self-extinguishing materials to meet fire safety standards.

- Ease of mounting: Bracket systems, quick-mount clips, and preperforated slats allow secure wall or ceiling fixing while allowing route adjustment before final tightening.

- Protection rating: Enclosures (surface or flush) often carry IP ratings (e.g. IP40, IP65) depending on intended environment, ensuring dust or moisture ingress is controlled in sensitive installations.

Internally, conductive parts or grounding paths are separated from mechanical structure but may include grounding clips or metal inserts where necessary. Cable clamps, strain reliefs, and partition walls within enclosures prevent internal stress on conductors.

Variants and Comparative Trade-offs

Elektro Plast provides diverse families:

- Conduit Systems / Corrugated Tubes / Rigid Tubes: Used to protect flexible wiring, especially in walls, under floors, or across exposed runs. Flexible corrugated tubes are good for curved paths; rigid tubes offer higher mechanical protection.

- Mounting Slats / CTS Systems: Flat channel rails used behind trunking or cable ladders to mount conduits, boxes, or devices. Perforations simplify fixing.

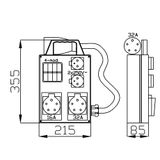

- Enclosures & Junction Boxes: Surface or flush-mounted, they house connectors, switches, or control modules. Choose based on environment and required IP rating.

- Mounting Accessories / Brackets / Fittings: Clips, clamps, quick-mount brackets, couplings, elbows, T-junctions — they permit routing at turns, transitions, branching, or structural mounting.

- Specialized Components: Halogen-free variants, UV-resistant profiles, parts for photovoltaic (PV) installations, and lightning-protection conduit elements.

Trade-offs include: flexible vs rigid conduits (flexible eases installation in tight bends but less robust); compact enclosures vs more depth (compact saves space but limits wiring cross-section); standard plastic vs halogen-free (halogen-free is safer in fire but more costly).

Performance, Standards, and Reliability

Key performance attributes of Elektro Plast installation systems:

- Mechanical strength: Ability to handle bending, impact, and external loading without cracking or deformation.

- Thermal stability: Materials must tolerate ambient temperature ranges (e.g. –20 °C to +60 °C) without excessive expansion or shrinkage.

- Flame and smoke performance: Use of self-extinguishing or halogen-free materials ensures compliance with fire safety codes.

- Ingress protection (IP) for enclosures and junction boxes depending on exposure (dust, moisture).

- Dimensional tolerance and fit: Fittings must maintain tight clearances and fit flush with slats or conduits to prevent stress points.

- Chemical resistance and UV stability for external installations — plastics must resist degradation in sun or harsh environments.

Quality control in extrusion, molding, and assembly is critical; misalignment of couplings or warpage causes poor sealing or stress in runs.

Installation and Integration Best Practices

- Plan routing logic first: Map cable paths, junction box locations, bends and drops before ordering parts. Avoid overlong runs or sharp bends that raise stress.

- Fix spacing and support: Support conduits and slats at regular intervals dictated by local code (e.g. every 0.5–1 m depending on load). Use proper brackets to prevent sagging.

- Allow thermal expansion: Leave slight expansion gaps in long runs; rigid systems should not be over-constrained.

- Seal entries properly: Use appropriate grommets, glands, or seal rings at enclosure or through-wall penetrations to maintain IP integrity.

- Segregate power and control wiring: Use separate duct zones or partitions to limit electromagnetic interference.

- Grounding and bonding: When metal parts (e.g. grounding rails) are used, bond them correctly to the earth system to avoid floating conductive paths.

- Test before closure: Before final sealing, inspect cable continuity, insulation resistance, and fit; make changes before permanent locking.

Maintenance, Common Failure Modes, and Lifecycle

Failures in installation systems are rarely catastrophic; common issues include:

- Loose brackets or sagging due to vibration or thermal cycling.

- Cracked or broken fittings under impact or stress concentration.

- Seals failing on enclosures or junctions, leading to moisture ingress or dust buildup.

- UV degradation causing embrittlement in exposed runs.

- Misaligned joints causing cable pinch or stress.

Maintenance regime:

- Periodically inspect alignment, fastener torque, and integrity of seals in external or industrial environments.

- Replace suspect fittings or clips promptly rather than patching.

- Keep spare key accessories (elbows, clips, junctions) on hand — failure replacement is easier than retrofit under pressure.

- Document as-built routing and variations from plan so future teams know what’s behind finishes.

Well-chosen systems with good materials can remain reliable for 20–30+ years, but only if mechanical and environmental stress is managed.

Selection and Procurement Guidelines

When specifying or procuring Elektro Plast installation parts:

- Define environmental class (indoor, outdoor, industrial exposure) to pick correct IP, UV, or halogen-free materials.

- Estimate cable quantity, fill factor, bend radius, and future expansion — oversize conduit early to allow growth.

- Choose modular systems so couplings, bends, and slats are interchangeable.

- Demand full datasheets: dimensional tolerances, mechanical ratings, fire class, material specifications.

- Order spares of high-use and critical components (clips, junctions, connectors).

- Confirm compatibility: e.g. slat systems must match mounting holes of conduit clips, alignment across runs.

- Evaluate supplier support: cut-to-length options, custom RAL colors, logistical consistency.

Distribution and Project Support by Bank of Lamps

Bank of Lamps distributes the full line of Elektro Plast installation systems across Europe, supplying everything from conduits and mounting systems to enclosures and accessories. Our warehouse in Latvia stores key components with traceable batch data and full technical documentation.

We assist procurement and contractor teams with routing design, part matching, and layout optimization. Project quotes include mixed-item bundles, volume discounts, consolidated shipping to UK, Germany, Netherlands, France, Spain, Belgium, Baltics, and post-payment options for qualified partners. When you source Elektro Plast installation systems via us, you gain consistency, engineering support, and lower risk of incompatible parts in your installations.