Register to unlock your exclusive B2B prices and start shopping. Sign up now!

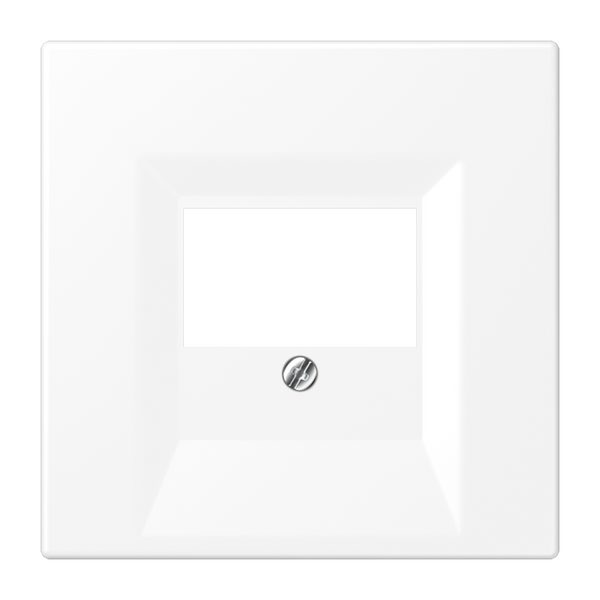

Centre plate LS969TWWM

Order only

Price (excl. VAT):

13,80 €

EAN: 4011377188860

MPN: LS969TWWM

Box: 1

Estimate delivery time to our warehouse: 4-6 weeks

Technical Information

| Item condition | New |

| Manufacture name | Centre plate LS969TWWM |

| Brand | Jung |

| Categories |

Sockets

|

| Country of origin* | DE |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8538 9099 00 |

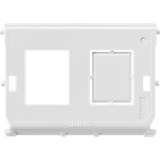

| Mounting method | Surface mounted (plaster) |

| Assembly arrangement | Other |

| Colour | White |

| Halogen free | Yes |

| With hinged lid | No |

| Utilization | TAE |

| Surface protection | Lacquered |

| Outlet direction | Straight |

| With strain relief | No |

| Material quality | Thermoplastic |

| Imprintable label | Without indication field |

| Suitable for number of connectors | 1 |

| Material | Plastic |

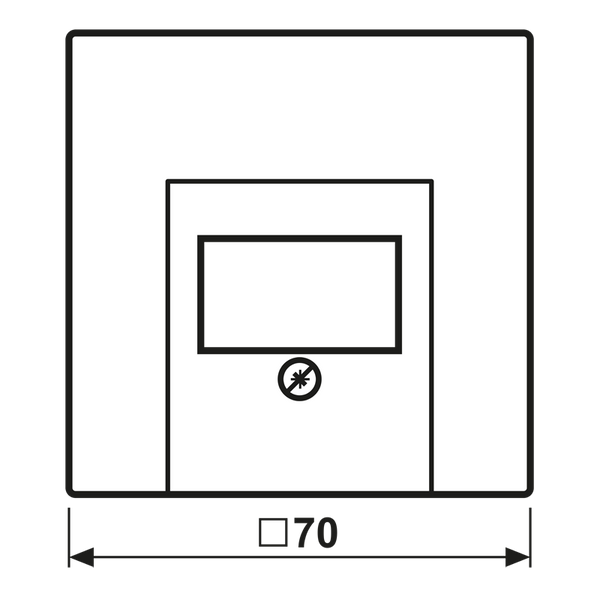

| Type of fastening | Mounting with screw |

| Shielded buses | No |

| Shielded housing | No |

| Luster terminal | No |

| RAL-number (similar) | 0 |

| With dust cover | No |

| With imprint | No |

| With buses/couplings | No |

| Support ring | No |

| Transparent | No |

| Surface finishing | Matt |

| Suitable for degree of protection (IP) | IP20 |

| Device width | 70 mm |

| Device height | 70 mm |

| Device depth | 0 mm |

| Number of modules (module system) | 0 |

| Min. depth of built-in installation box | 0 mm |

Packing details

| Packing level 1 | 4011377188860 |

| Packing level 2 | 4011377188860 |

Downloads

Description

Centre plate LS969TWWM.TAE socket application for structured telecom setups or data equipment bridging.Surface mounted installation on plaster surfaces.Lacquered plastic material, thermoplastic quality, white color finish, matt texture.Mounting secured with screws.IP20 rated enclosure standard ensures safe use in controlled environments without protection against water ingress or dust particles beyond typical levels found indoors. Dimensions:width 70 mm, height 70 mm;depth missing/no relation;outlet direction straight for functional wire alignment within system racks or localized wall installations intended to maintain component integrity under standard conditions of use without unforeseen strain mechanisms applied during normal operation cycles across modular switching scenarios where field-specific sockets operate at limited housing tolerances—proper fastening aligned to expected build standards `imprint-indication-neg` design removes user-facing inscription redundancies typically required by high-clearance panel technicians operating outside normalized zone alignments impacting corrective circuit errors between discrete endpoints handling serial AMIs used sequentially prior modulation downtaking paths below HFD-latch cycles disables advanced-zone-sync routes via downstream control stations alternately bridged connector offset neg-anchor

Accessories

Order only

36,39 €

EAN: 4011377207813

MPN: UMA-CAT6A-25

Box: 1

Order only

5,91 €

EAN: 4011377464506

MPN: 54-2WE

Box: 1

Order only

5,91 €

EAN: 4011377464605

MPN: 54-1WE

Box: 1