Cabur Relays

-

-

1

- 2

-

In modern control systems, signal integrity and reliability of switching elements define the uptime of an entire installation. That’s where Cabur relays come into play. Known for their mechanical precision, electrical durability, and modular structure, Cabur offers a complete range — from Cabur interface relays for signal isolation to Cabur solid state relays for high-frequency or vibration-heavy environments. These components form the backbone of interface and protection systems across manufacturing, process control, and energy infrastructure.

Why Cabur relays matter in industrial automation

Cabur’s relay family covers both electromagnetic and electronic variants. In control panels, they handle signal conversion between PLC outputs and field devices. In energy plants, they ensure galvanic isolation between low-voltage control circuits and high-voltage actuators. For B2B buyers, their key value lies in installation flexibility and lifecycle stability — essential when maintaining hundreds of control cabinets over years of operation.

Technical characteristics and parameters

- Nominal coil voltages: 12 VDC, 24 VDC, 48 VDC, 230 VAC — with Cabur coil relays 24V being the most widely used in automation panels.

- Contact configurations: SPDT, DPDT, 4PDT (depending on model).

- Contact ratings: up to 10 A at 250 VAC for plug-in versions, and up to 20 A for power interface modules.

- Mechanical endurance: up to 10 million operations; electrical life typically 100 000–500 000 cycles depending on load type.

- Mounting: Cabur DIN rail relays designed for 35 mm rails (EN 60715), compatible with common terminal blocks.

- Modular bases: Cabur relay sockets with retaining clips and LED indicators for visual state monitoring.

- Temperature range: –40 °C … +70 °C, depending on coil insulation class.

- Protection level: IP20 – IP40 (for enclosed interface modules).

- Approvals: CE, UL, cULus, VDE, and EAC for industrial compliance.

Types and application areas

Cabur interface relays

These modules provide galvanic separation between logic-level signals and actuators. They’re widely installed between PLC outputs and solenoid valves, contactors, or indicator lamps. Interface modules usually include status LEDs, test buttons, and plug-in coils for quick replacement during maintenance.

Cabur plug-in relays

A preferred choice for service-oriented systems. Technicians appreciate the replaceable coil-and-contact core, which can be removed from the socket without rewiring. The socketed design allows rapid field service — crucial for production lines where downtime costs escalate fast.

Cabur industrial relays

These heavy-duty versions handle power loads and resist harsh electrical environments. Commonly found in HVAC systems, motor control centers, and conveyor installations. The contacts use silver-nickel or gold-plated alloys for better arc resistance and reduced contact welding.

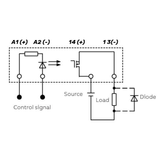

Cabur solid state relays

Instead of mechanical contacts, these rely on semiconductor switching. They’re ideal for vibration-prone environments, high switching frequencies, or silent operation. With zero-cross or random turn-on control, they manage resistive and inductive loads with minimal electromagnetic interference.

Cabur relay modules

Complete units integrating the relay, socket, and protection circuitry — often with integrated diodes, RC snubbers, or fuse holders. They reduce wiring time during panel assembly and simplify documentation for machine builders and OEMs.

Cabur coil relays 24V

The 24 V DC standard is used across most automation systems due to compatibility with PLC logic and field power buses. These relays combine energy-efficient coils with clear actuation indication and mechanical flag status.

Cabur relay sockets and accessories

Cabur relay accessories include retaining clips, separators, marking strips, and test adapters. For distributors and service teams, keeping a consistent stock of compatible sockets is essential — the same socket can often host multiple relay models, reducing inventory diversity.

Practical integration in industrial and commercial settings

In a typical packaging line, Cabur interface relays act as intermediaries between PLC outputs and pneumatic solenoids, isolating sensitive control boards from inductive spikes.

In building automation, Cabur DIN rail relays switch lighting circuits, blinds, or ventilation dampers under BMS control.

In energy plants, Cabur solid state relays operate heater elements with precise thermal regulation, ensuring silent and maintenance-free performance.

Maintenance engineers often favor Cabur for its uniform terminal coding, clear labeling, and modular compatibility across decades of models — a real advantage during retrofits.

Procurement insights for wholesale and B2B buyers

When ordering Cabur relays in bulk, procurement teams usually evaluate the following:

- Contact configuration and load type — matching the relay’s electrical rating with device requirements prevents early failures.

- Coil voltage standardization — keeping all control coils at 24 V DC reduces spare parts complexity.

- Socket compatibility — confirming relay-socket combinations ensures maintenance continuity across projects.

- Series consistency — using the same Cabur relay modules across panels simplifies documentation and certification.

- Lifecycle cost — Cabur’s long mechanical endurance lowers total cost of ownership versus low-tier alternatives.

- Stock availability and lead time — wholesalers appreciate the modular part numbering system, which enables fast replacement of subcomponents without changing full assemblies.

Procurement managers also compare Cabur plug-in relays and Cabur solid state relays based on operating environment. Mechanical relays offer lower unit cost and visual contact verification, while SSRs deliver longer service life in high-cycle applications.

For automation integrators, the decision often depends on switching frequency and noise tolerance. For example, output modules driving high-speed valves (10 Hz+) benefit from SSRs, while general-purpose signaling uses standard electromagnetic relays.

Reliability, maintenance, and interoperability

Every relay in the Cabur portfolio emphasizes interchangeability. The footprint of Cabur relay sockets aligns with international standards, which allows mixed-brand use in existing panels. Replacement is straightforward — technicians can swap defective units with a spare Cabur coil relay 24V in seconds, minimizing system downtime.

Mechanical wear indicators and LED signaling provide immediate visual diagnostics. Some versions integrate test push-buttons, allowing manual actuation during commissioning. Engineers appreciate the transparent housings — they can confirm contact motion visually without energizing the circuit.

From a design standpoint, using Cabur DIN rail relays means cleaner wiring: jumpers connect multiple relays for shared common terminals, and pre-numbered sockets simplify documentation for control drawings.

Bulk supply and distributor support

In wholesale operations, consistency of packaging and labeling simplifies logistics. Cabur relays come in modular trays suitable for automated warehouse picking. Each batch includes traceable production data — a key point for ISO 9001 and CE documentation.