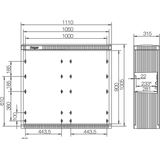

Berker Electric box (breaker panel)

10 endcaps for bubar 1P

Enclosure,vector, IP5x, 6M

10 endcaps for bubar 4P

Endcap for busbar 3P+N

Black handle LBS 800A

When you walk into a switch room or a utility closet, one of the first things that hits you is how clean the distribution boards look — neat rows, clear doors, no wires spilling out. That’s exactly the territory where Berker distribution boards shine. They’re reliable, versatile, and built so that both install and future service go smoothly.

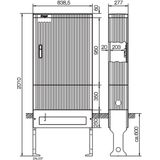

Berker Flush-mounted or surface-mounted — pick what fits

Depending on your wall type or mounting preference, Berker offers both flush-mounted distribution boards and surface-mounted distribution boards. Flush ones recess into drywall or concrete, leaving only the door visible. Clean and discreet. Surface-mounted ones sit proud of the wall — easier to install on finished interiors, or where wall depth is limited.

Whichever you choose, the frame tolerances are tight, the door fits flush, and the finish stays clean. No warped edges or uneven gaps.

IP65 and protection for tough environments

Some electrical rooms get dusty. Others see water drips or washdowns. That’s why Berker also offers distribution boards IP65 — fully sealed against dust and jets of water. You can use them in garages, outdoor substations, corridors, or any place where protection matters.

Even with sealing gaskets, the doors open cleanly and stay true — no sagging or warping from moisture or temperature.

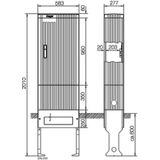

From small 12-module to 24-module setups

On smaller circuits — like a control room or a small machinery panel — a Berker distribution board 12 modules size is compact yet capable. You get enough space for incoming, outgoing circuits, and even spare slots without crowding.

For bigger needs — lighting circuits, HVAC feeds, or full branch installations — the Berker distribution board 24 modules gives you headroom. Wire them cleanly, route neutrals and earth bars, and the rows stay logical rather than messy spaghetti.

Berker modular spacing is consistent, so expansion or reconfiguration later doesn't force a rework of the entire cabinet.

Plastic or metal — choose your enclosure

Many Berker boards come in plastic distribution board versions — lightweight, corrosion-resistant, ideal for interiors or less demanding industrial zones. The doors are transparent or opaque, sturdy enough for repeated access.

Metal enclosures are also used — for heavier duty, better thermal dissipation, or where mechanical strength matters. Whatever material you pick, Berker ensures that mounting points, knockouts, and structural support are clean and usable.

Berker Transparent doors and DIN rail enclosures

One of the nice modern touches is Berker enclosure with transparent door options. You get visibility into the circuits without opening the door — status LEDs, tripped breakers, and labeling all visible. Good for maintenance checks, quick diagnostics, and safety compliance.

Inside, everything is DIN rail–based. Berker includes Berker DIN rail enclosure features in their distribution boards — stable rails, proper spacing for breakers, busbars, and wiring. That means integration is clean, modular, and repeatable across different board sizes.

Berker Small distribution boards for compact installations

Sometimes you don’t need a full 24-module box. Berker small distribution board variants are compact and clever. They pack turnout space, a door, and proper wiring room, all without wasting wall area. Perfect for satellite panels, remote rooms, or retrofit spots.

Don’t mistake “small” for “weak” — Berker designs these with all the same protection, spacing, and accessibility logic.

Real benefits for real projects

What I like about good Berker boards (having seen them installed in offices, factories, data centers) is how they think ahead. Cable entries are well placed. Knockouts don’t interfere with wiring. Doors can be hinged left or right. Labeling grooves are included.

Once you wire it correctly, you close that door — and for years, it stays functional. No rattles, no warps, no mysterious discoloration. That’s the kind of reliability electricians pay attention to.

At Bank of Lamps, we supply Berker’s full distribution board range — flush, surface, IP65, 12- and 24-module, plastic and metal, with transparent doors and DIN-compatible interiors.