Allen-Bradley Motor Controls and Drives

Allen-Bradley control gear forms the operational core of modern automation and motor-control systems. Designed for precision, longevity, and interoperability, these control devices ensure that electrical power is delivered, switched, and managed safely across demanding industrial environments. Manufactured under Rockwell Automation standards, Allen-Bradley control equipment combines robust materials, compact design, and compliance with IEC and UL norms.

Within the range, engineers can find everything from compact relays and contactors to modular control modules and full motor control assemblies. Rated across voltage classes up to 690 V and current capacities exceeding 630 A, Allen-Bradley industrial control gear is known for mechanical endurance and heat tolerance. The result is reliable operation in manufacturing plants, energy facilities, and control cabinets that require both precision and safety.

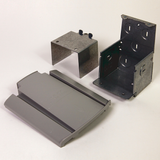

Allen-Bradley Motor Control Gear — Core Variants and Functions

Allen-Bradley motor control gear covers contactors, overload relays, and motor starters used to manage and protect induction motors. The Compact 100-C and Bulletin 140 series deliver high-density configurations for control panels with limited space. They feature mechanical life up to 10 million operations, screw or spring clamp terminals, and wide coil voltage options (24 V DC / 230 V AC).

These control devices allow safe motor starting, reversing, and load disconnection. Their modular accessories — auxiliary contacts, surge suppressors, and terminal covers — simplify customization. Procurement managers often select by current range, auxiliary contact configuration, and conformity with IEC 60947-4-1. For bulk orders, standard carton multiples and identical MPN codes ensure seamless BOM uploads and consistent pricing.

Allen-Bradley Switching Gear and Control Equipment for Specialized Applications

For switching and isolation, Allen-Bradley switching gear includes molded-case switches, isolators, and disconnect units rated for high mechanical stress and electrical endurance. These components are engineered to handle frequent switching cycles in manufacturing cells, conveyors, and automated machinery.

Specialized subranges — such as the 194E modular disconnect switches or the 100-E contactors — provide extended durability under vibration and thermal variation. Materials like silver-nickel contact alloys and reinforced thermoplastics enhance performance. In sectors such as mining or food processing, engineers prioritize chemical resistance, ingress protection, and terminal accessibility. Bulk procurement usually compares terminal type (cage-clamp vs screw), enclosure compatibility, and ambient temperature limits.

Allen-Bradley Control Modules and Advanced Units with Smart Protection

Beyond standard gear, Allen-Bradley control modules integrate monitoring, communication, and diagnostic functions. Examples include Bulletin 193 E-series electronic overload relays and 156-series soft starters that interface with PLCs or Ethernet/IP networks. These advanced control devices feature built-in protection against overload, phase loss, and stall conditions, and many support remote parameterization.

Industrial users benefit from the data integration — energy monitoring, trip history, predictive maintenance alerts — that helps reduce downtime. Such gear often complies with IEC 60947-4-2 and EN 60947-5-1. OEMs and system integrators choose them for intelligent control cabinets, process lines, or HVAC automation projects requiring high data transparency.

Compatibility and Integration Notes

Allen-Bradley electrical control gear is designed to integrate seamlessly with the wider Rockwell Automation ecosystem — including PowerFlex drives, Guardmaster safety systems, and CompactLogix controllers. Standard DIN-rail or panel-mount configurations simplify assembly. Communication options include Ethernet/IP, DeviceNet, and Modbus gateways for digital supervision.

Mounting hardware fits within modular enclosure grids, enabling mixed installations with relays, circuit breakers, and automation modules. This compatibility reduces commissioning time and simplifies future servicing for maintenance teams.

Technical and Safety Standards

All Allen-Bradley industrial control gear complies with major international directives: IEC 60947, UL 508, CE, and RoHS. Insulation class typically reaches Class II, with IP 20–IP 65 enclosures depending on the assembly. Contact materials and plastics are tested for dielectric strength, thermal endurance, and flammability (UL 94 V-0). Devices operate from -25 °C to +70 °C and undergo mechanical tests up to 10 million cycles. Certificates are available per batch and include EAN / MPN traceability for procurement audits.

Where Allen-Bradley Control Gear Is Used

Allen-Bradley control equipment serves a wide range of industrial and infrastructure applications:

- Motor control centers and distribution boards.

- Manufacturing automation, conveyors, and packaging lines.

- Energy generation and renewable installations.

- Building management systems (HVAC, elevators, pumps).

- Process industries (chemical, food, and water treatment).

Engineers value the combination of durability, accuracy, and integration readiness — essential for long service cycles and low maintenance downtime.

How to Select the Right Allen-Bradley Control Gear

- Determine load and motor rating — match contactor current and relay settings to operational load.

- Assess environment — dust, temperature, or vibration affect enclosure and material choice.

- Check control voltage — verify coil type (AC/DC) and range (24, 110, 230 V).

- Integration — ensure communication ports or expansion modules align with PLCs or drives.

- Compliance — confirm IEC and UL certificates for the destination market.

- Procurement — use official MPNs for ERP integration; align quantities to carton or pallet MOQ.

Common mistake: mixing coil voltages or omitting auxiliary contacts in motor-starter assemblies. A brief technical consultation before bulk purchase prevents costly rework.

Wholesale Supply of Allen-Bradley Control Gear by Bank of Lamps

Bank of Lamps supplies the full Allen-Bradley range — control gear, control modules, switching gear, and motor-control devices — for industrial and OEM applications. Our warehouse in Latvia maintains real-time stock visibility and access to Rockwell partner inventory.

We offer custom B2B pricing, fixed-term quotations, and volume discounts. Quote requests receive a response within one hour. Orders can be placed using EAN or MPN codes for automated processing.

Shipping covers the UK, Germany, Netherlands, France, Spain, Belgium, and Baltic countries. We provide post-payment options (up to 30 days for established clients), consolidated deliveries for multi-brand projects, and detailed shipment tracking. Procurement teams gain reliable access to verified Allen-Bradley electrical control gear — with full documentation, fast logistics, and long-term reorder support.