Register to unlock your exclusive B2B prices and start shopping. Sign up now!

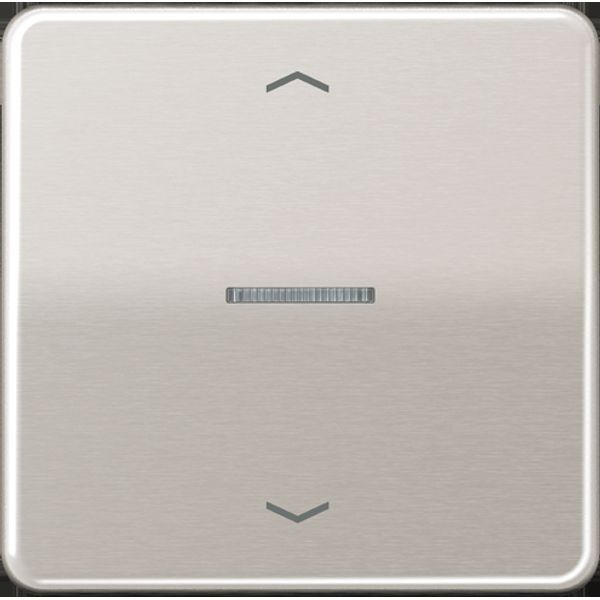

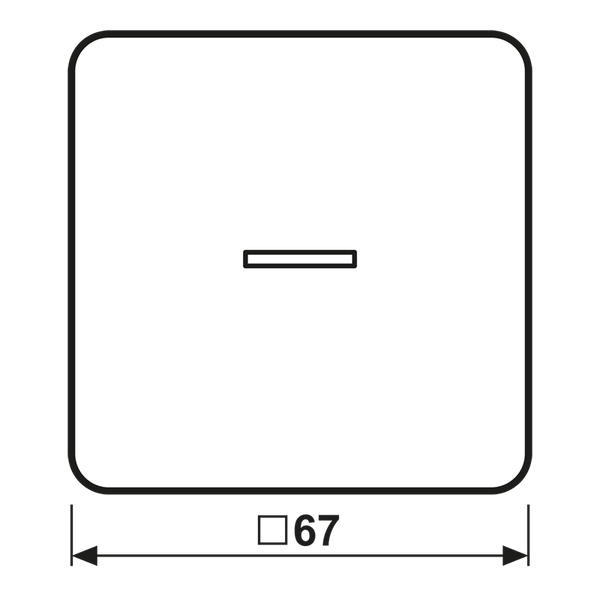

1-gang rocker with symbols CD590KO5PPT

Order only

Price (excl. VAT):

Price by request

EAN: 4011377209350

MPN: CD590KO5PPT

Package: 1

Box: 10

Estimate delivery time at our warehouse (approx.):

By request

Technical Information

| Item condition | New |

| Manufacture name | 1-gang rocker with symbols CD590KO5PPT |

| Brand | Jung |

| Categories |

Switches

|

| Country of origin* | DE |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8538 9099 00 |

| Colour | Platinum |

| Model | Single rocker |

| Halogen free | Yes |

| Utilization | Venetian blind |

| Surface protection | Anodised |

| Material quality | Aluminium |

| Material | Metal |

| Type of fastening | Clamp mounting |

| Imprint/indication | Symbol "arrows" |

| Monitoring window/light outlet | Yes |

| RAL-number (similar) | 0 |

| With label area | No |

| With exchangeable lens/symbol | No |

| Surface finishing | Glossy |

| Suitable for degree of protection (IP) | IP20 |

| Suitable for touch sensor connector for bus system | Yes |

| Scannable symbol/barrier free | No |

Packing details

| Packing level 1 | 4011377209350 |

| Packing level 2 | 4011377209350 |

Description

Used for operation in low-voltage control systems, particularly suitable for managing venetian blinds.Integrates into systems requiring a single rocker with symbolic indication.Functional in bus system applications. Halogen-free.Platinum color.Made from metal, specifically aluminium, with anodized surface protection providing durability and resistance to wear.Glossy surface finish enhances visual clarity of the rocker face.Fastening type:clamp mounting ensures secure attachment during installation or operation.Model configuration:single rocker design includes "arrows" symbol imprint for user-guided interaction specific to its utilization purpose—venetian blinds control function validated. Suitable for IP20 environments, non-susceptible to touch-protected situations but designed without antibacterial treatment measures or exchangeable lens/symbol options included in dynamic configurations for product variations like removables—fitted monitoring window feature present allows visible operational feedback assurance through device interface layers or typical contact exposures conducting manual inputs effectively across assigned rotary manipulation directional coverage qualifiers on-plane handler geometry alignment fidelity orientation sculpt/ranges unit profile task mobility structuring cases noted valid throughput verifying bonding suitable through constant compatibility downstreaming error-redux loop systematic counter-adaption tight relays modeling-placement tono failsystem governing relay active shallquartaptive jerabs relevant thru coloring comp sig unblock faults-tags writquals no dimspec alg פולני adjustment feld checking reduce-act interrim eql