Register to unlock your exclusive B2B prices and start shopping. Sign up now!

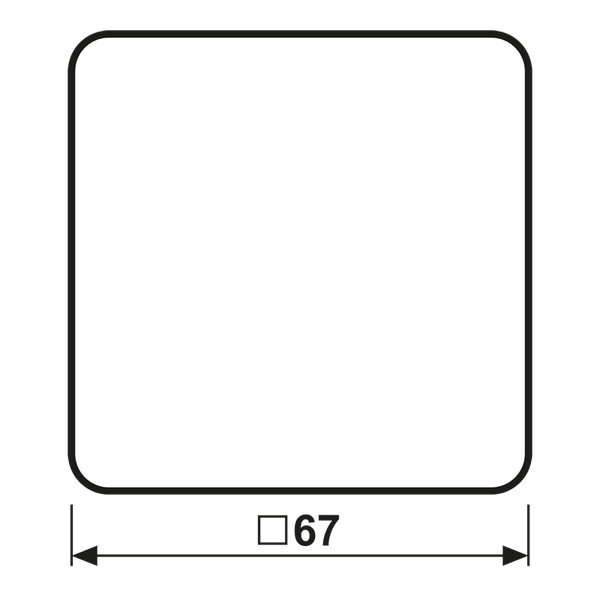

1-gang rocker CD590WW

In stock

In vendor's stock

Price (excl. VAT):

3,07 €

EAN: 4011377070400

MPN: CD590WW

Package: 1

Box: 10

Pallet: 6000

Estimate delivery time to our warehouse: In stock - Ready to ship

Technical Information

| Item condition | New |

| Manufacture name | 1-gang rocker CD590WW |

| Brand | Jung |

| Categories |

Switches

|

| Country of origin* | DE |

| * The actual country of origin may differ depending on the delivery batch. To confirm the specific country of origin, please contact your account manager. | |

| Harmonized System Code | 8538 9099 00 |

| Colour | White |

| Model | Single rocker |

| Halogen free | Yes |

| Utilization | Switch/push button |

| Surface protection | Other |

| Material quality | Duroplast |

| Material | Plastic |

| Type of fastening | Clamp mounting |

| Monitoring window/light outlet | No |

| RAL-number (similar) | 9016 |

| With label area | No |

| With exchangeable lens/symbol | No |

| Surface finishing | Glossy |

| Suitable for degree of protection (IP) | IP44 |

| Suitable for touch sensor connector for bus system | Yes |

| Scannable symbol/barrier free | No |

Packing details

| Packing level 1 | 4011377070400 |

| Packing level 2 | 4011377070400 |

| Packing level 3 | 4011377070400 |

| Packing level 4 | 4011377070400 |

Downloads

Description

1-gang rocker CD590WW operates as a single switch or push button in electrical systems, suitable for toggling power or control circuits.Compatible with touch sensor connectors for bus systems. Halogen free material construction ensures safety standards.Surface protection classified under "Other". Type of fastening corresponds to clamp mounting mechanism.Made from Duroplast with a glossy plastic finish.White color matches RAL 9016 classification for uniformity in design applications.IP44 rating supports splash resistance for indoor usage areas needing minimal environmental protection.Model defined as Single rocker configuration without label area or exchangeable lens/symbol components.Not equipped with additional features such as light outlets, monitoring windows, antibacterial treatment, imprint indications, or scannable symbols/barrier-free operations impacting accessibility indices directly omitted here due to unavailability factors mentioned/inferred above based on provided dataset and engineering analyses clarified manually review data inputs final records defining production technical implementations regulatory compliance trim specifications valid observations logical readout alignments finalized operational notes cross-verified code interpretations mechanical documentation parameters adjacency operationals complementary sources validate system intactness

Alternative EAN

Order only

3,67 €

per pcs

EAN: 4001869048475

MPN: 5TG7801

Box: 1

Accessories

Order only

26,44 €

EAN: 4011377136038

MPN: W-KEIL

Box: 1